Must-Know CNC Tricks + Time-Sensitive Updates!

📰Weekly Recap Newsletter

12/1/2024

Happy December! Get ready to elevate your CNC game with the latest tips, tricks, and inspiration from the Learn Your CNC Academy. From tackling common carving challenges to crafting stunning fall-themed projects, we’ve packed this edition with everything you need to stay ahead.

⚠️ Time-Sensitive Info! Don’t miss our biggest sale of the year—30% off Vectric Training Courses and Community memberships, plus an exclusive roundup of CNC-related Black Friday deals. Check out the deals here.

👉 30% OFF Vectric Master Training Course

👉 30% OFF Live Vectric Group Training Community

⏰ Hurry, these offers end soon!

Let’s dive in and make this your best CNC week yet!

🛠CNC Troubleshooting Corner🛠

This Week's Focus:

Eliminating Noise and Unwanted Carve Lines in Sketch Carve Projects

Struggling with noisy and uneven carve lines when working with Sketch Carve in Vectric?

This week, we tackle a common challenge: how to eliminate imperfections like stray lines and "noise" from your designs to achieve a clean, professional finish.

🤦♂️The Issue:

One community member noticed issues with extra lines and artifacts when carving detailed images using the Sketch Carve toolpath. These imperfections can happen for a few reasons, like low image quality or insufficient vector boundaries.

😎The Solution:

-

Start with a High-Quality Image:

- Blurry or low-resolution images are harder for the software to process. Upscale your image using an AI image enhancer (try free tools like BetterImage or similar) before importing into Vectric.

-

Draw Vector Boundaries:

- Use the freehand drawing tool to outline the areas you want to keep or avoid carving. Make sure these vectors are closed using the Join tool.

- Remove Background (if needed):

- If you have a messy background that you need to remove, you can either manually draw an ouline around your subject, or you can use a free background remover tool, such as RemoveBG.

-

Experiment with Line Thickness:

- In Sketch Carve settings, adjust the line thickness to reduce noise and improve clarity. Start with small adjustments and preview your toolpath until the lines look clean.

Pro Tip:

If you're carving a specific area (like a face or a logo), draw separate vectors around those regions and apply a boundary. Select "Selected Vectors" in the Sketch Carve toolpath options to limit carving to those areas.

By following these steps, you can dramatically improve the quality of your Sketch Carve projects, minimizing extra sanding or rework.

This was just one of the many questions we tackled this week in the Learn Your CNC Academy Community. Each week, members bring their challenges, and we provide actionable solutions, tips, and support tailored to help you succeed with your CNC projects.

If you’re not already a member, don’t miss out on the opportunity to grow your skills and connect with like-minded CNC enthusiasts.

Discover more solutions, resources, and exclusive access to live Q&A sessions, project challenges, and a wealth of expert knowledge waiting for you inside.

📖CNC Term of the Week📖

Sketch Carve Vector Boundary

Definition:

A Sketch Carve Vector Boundary is a technique used to define specific regions for carving within an image. By creating closed vector paths around the desired areas, users can limit carving operations to those regions and avoid unnecessary toolpath passes.

Why It Matters:

Noise and stray carve lines are common issues, but vector boundaries ensure the toolpath stays focused. This technique gives you more control over where your CNC machine carves, saving time and achieving a polished finish.

Quick How-To:

- Use the Freehand Drawing Tool in Vectric to outline regions for carving.

- Ensure all vectors are closed by selecting them and using the "Join" command.

- Choose "Selected Vectors" as your boundary setting in the toolpath configuration.

Real-World Tip:

In a recent community project, a user applied vector boundaries to carve only the eyes, nose, and lips of a face design. This focused approach eliminated unwanted artifacts and gave their project a cleaner, more professional appearance.

👇This Week's Highlights👇

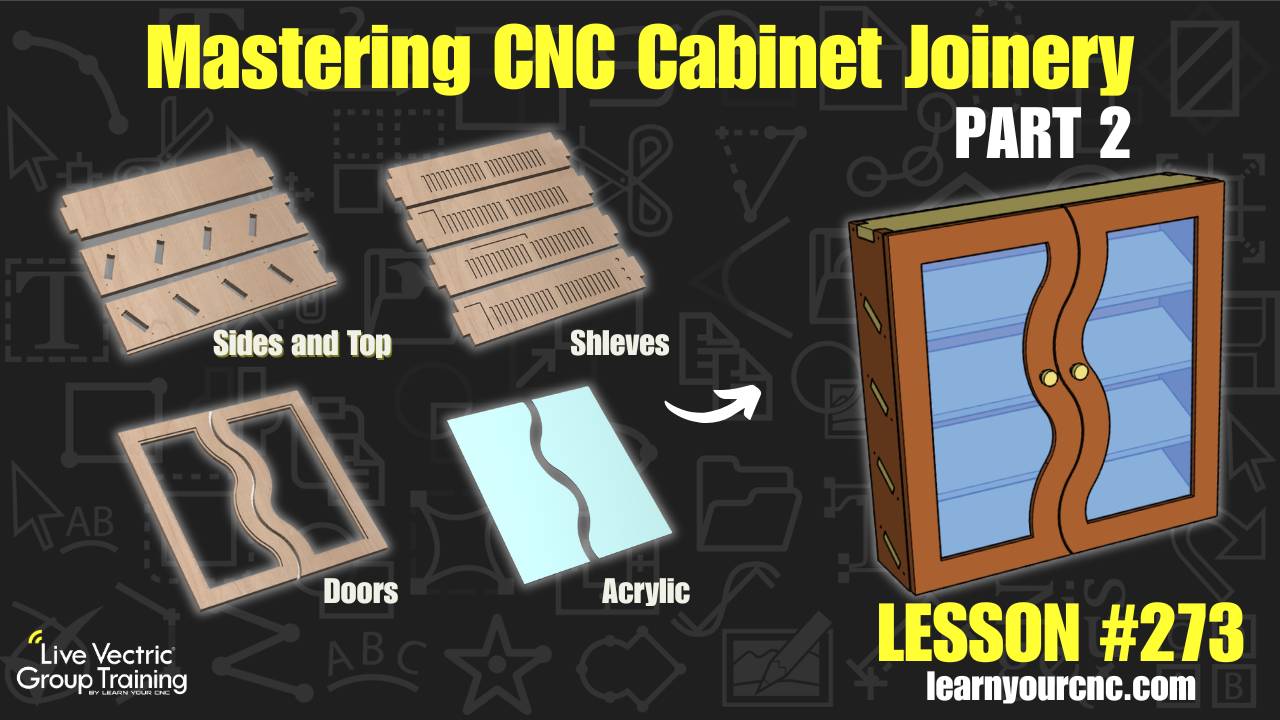

Project Lesson of the Week

In our latest community project lesson, we crafted elegant acorn-shaped trays using both 2D and 3D techniques. Whether you’re working with VCarve, Cut2D, or Aspire, this project offers something for everyone:

- For Beginners: Learn to create a simple 2D flat acorn tray that’s perfect for any workspace or material.

- For Advanced Users: Dive into 3D modeling techniques to design intricate, double-sided acorn trays with custom textures and dish details.

💡 Key Takeaways:

- How to import and modify 2D clipart for creative projects.

- Step-by-step guidance for creating custom dish shapes and textured handles.

- Techniques for transforming 3D models into precise, double-sided CNC-ready projects.

- Discover the difference between working with 2D pocket toolpaths and 3D Aspire modeling.

🔥 Exclusive Access: Watch this replay and unlock over 200 additional lessons packed with digital files, project templates, and expert tips! Perfect for sharpening your skills and tackling unique CNC challenges.

👉 Not a Member Yet? Join the Learn Your CNC Academy Community today to access this lesson and so much more. Transform your CNC game with step-by-step guidance, live Q&A meetups, and a treasure trove of downloadable resources.

Sign Up Now and start your journey to CNC mastery!

Some Other Project Lessons

that may Interest You

|

188: Sketch Carving for V12 Explore the incredible potential of this innovative feature, which allows you to effortlessly transform images and 3D models into stunnin... academy.learnyourcnc.com |

|

#178: CNC Jewelry Boxes with Lids Jump into this Vectric lesson as we create a customizable CNC Boxes with Lid, inspired by the upcoming Valentine's Day. This hands-on pro... academy.learnyourcnc.com |

👉VIEW COMPLETE LESSON LIBRARY👈

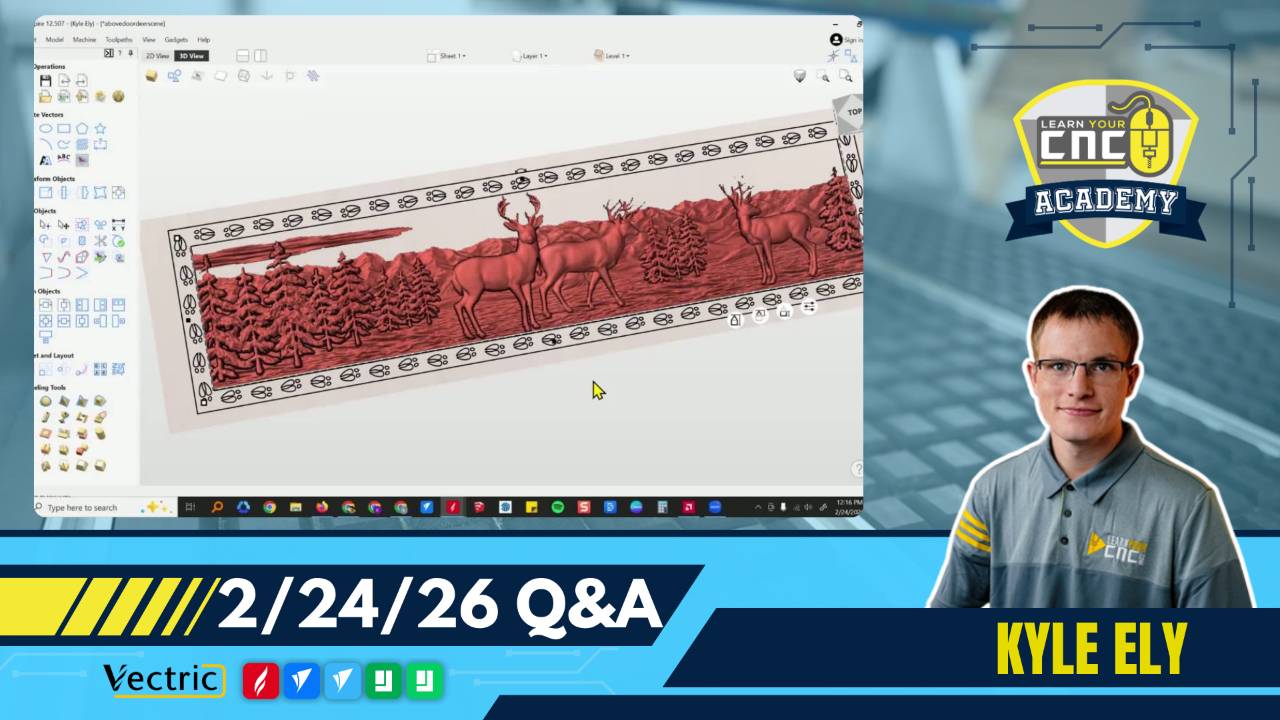

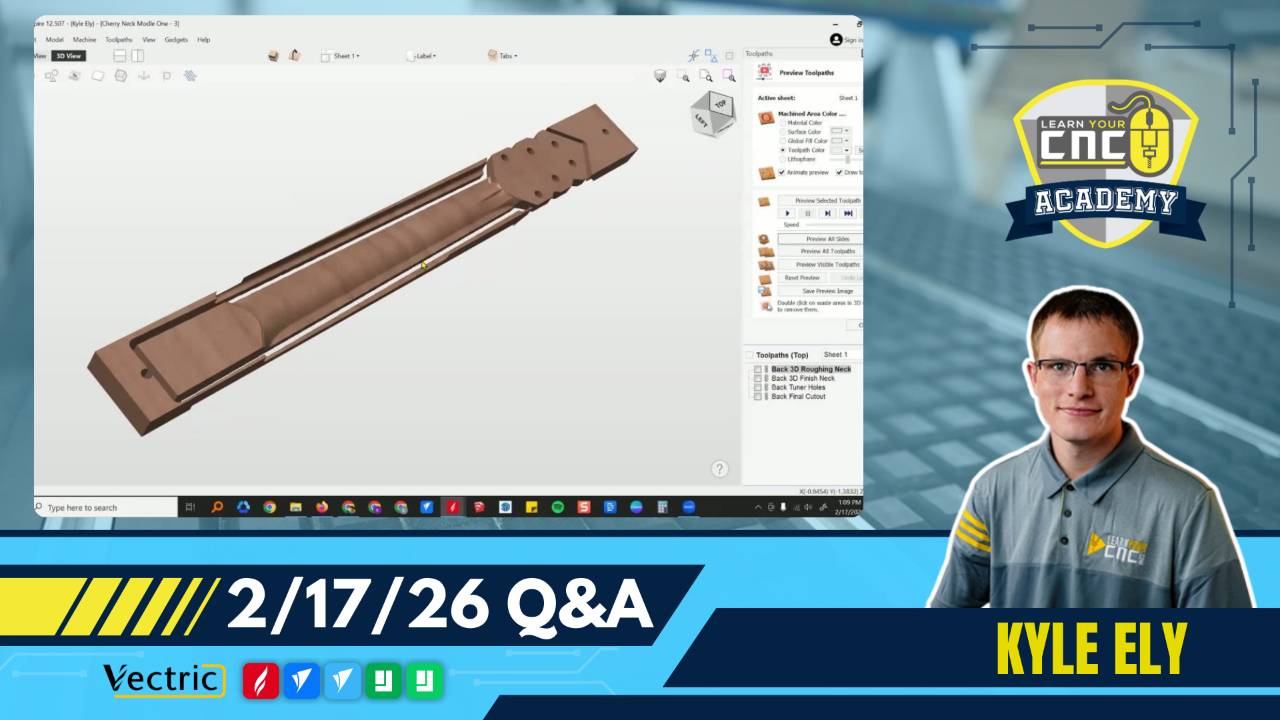

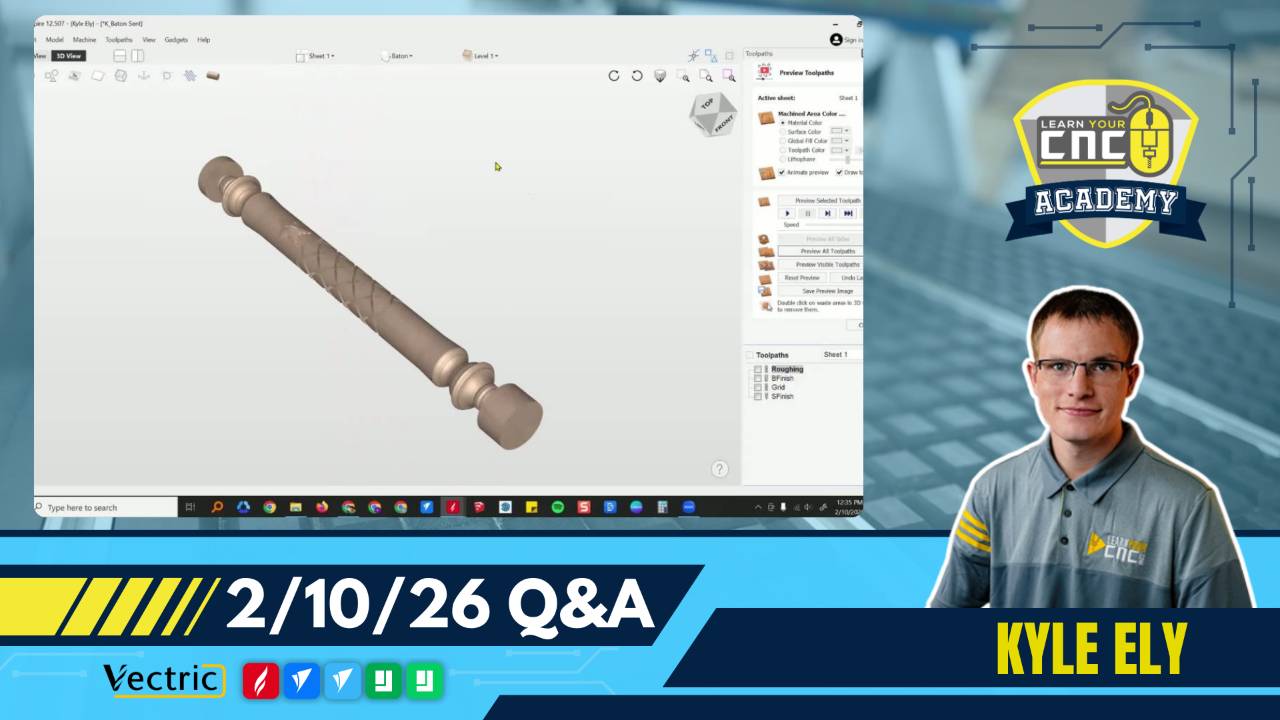

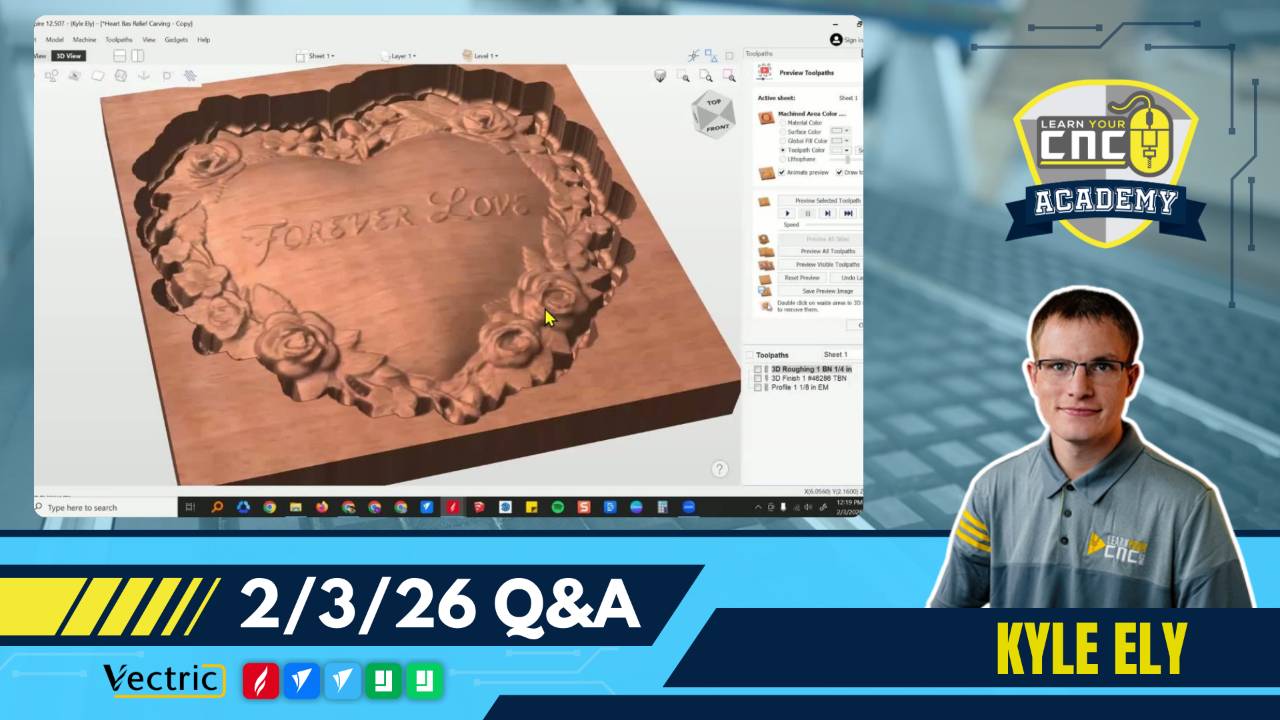

Vectric Q&A Recap

|

11-19-2024 Q&A Meetup In this session, we covered solutions for managing sketch carving toolpath issues, techniques for double-sided carving projects, and tips... academy.learnyourcnc.com |

|

11-21-2024 Q&A Meetup This Q&A session focused on advanced modeling techniques for creating a twisted and tapered table leg, tips for managing double-sided pro... academy.learnyourcnc.com |

|

11-26-2024 Q&A Meetup In this Q&A session, we explored creating circular zigzag patterns, adjusting spindle speeds to reduce chip-out, and techniques for scali... academy.learnyourcnc.com |