02-10-2026 Q&A: CNC Calibration, Rest Machining Ridges, and Production Strategies

Feb 10, 2026Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

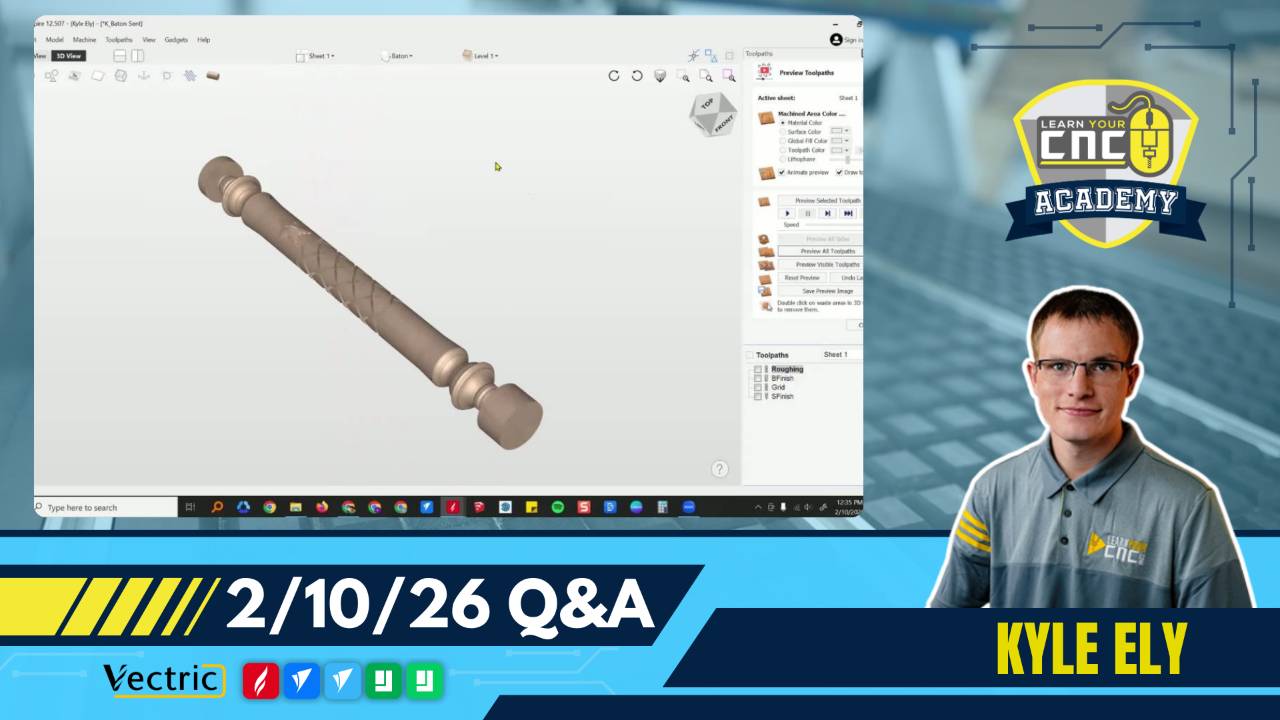

This session covers essential CNC maintenance and advanced project troubleshooting, including how to calibrate the X, Y, and Z axes for accuracy. We discussed strategies for eliminating ridges in 3D rest machining, work-holding techniques like the Micro Jig Match Fit system, and optimized toolpaths for high-volume production in cabinetry. The call also touched on vector repair for photo-to-3D conversions and handling grain tear-out in hardwoods like teak.

Key Tips Learned in this Q&A:

-

Calibration Verification: To ensure your machine is cutting accurately, use a sharp V-bit and a long ruler to measure actual travel versus commanded travel; adjusting "steps per inch" in your controller is necessary if they don't match.

-

Eliminating 3D Ridges: When using rest machining, set a "boundary offset" approximately equal to the radius of the larger tool to ensure the smaller bit clears away the material left behind by the first tool's radius.

-

Consistent Z-Zeroing: For complex 3D carves with multiple tool changes, zero off the same scrap block or the machine table rather than the carved surface to avoid depth discrepancies caused by material movement.

-

Preventing Grain Tear-out: For unsupported end-grain cuts (like heart-shaped trivets), run a profile toolpath first to define the edges before using large clearing bits, or use backer material to support the wood fibers.

-

Vector Trimming for Inlays: Use the "Scissors" tool with the "Rejoin closed vectors" option checked to clean up overlapping shapes for inlays; ensure you trim the outer boundary to connect different parts into a single continuous path.

Questions Answered in this Q&A:

-

00:08:20 - Will: Why is my machine consistently carving 2.625" high when I input 2.375"?

-

00:10:45 - How do you calibrate the Z-axis when the touch plate is still off by a 32nd of an inch?

-

00:14:14 - Alan: How can I eliminate deep ridges and grooves left along the edges during 3D rest machining?

-

00:22:44 - Dale: Do members have experience with the Micro Jig Match Fit or Bow products for material hold-down?

-

00:27:38 - Rainer: Is the measurement tool broken in the latest VCarve Pro patch (version 12.507)?

-

00:29:50 - Kevin: Why is my rotary project preview not showing the star or grid details correctly?

-

00:39:31 - William: How do I fix the hundreds of open/overlapping vectors created when tracing a bitmap for a photo frame?

-

00:43:08 - Dave: Is there a way to merge overlapping objects (like a bullet, hole, and letter) into one clean vector?

-

00:50:03 - Dale: Is it possible to export or print the Vectric tool database as a CSV or readable file?

-

00:55:30 - Bruce: Should I use a common vector or an offset to prevent white oak lines between shield border inlays?

-

01:07:55 - Lyle: How do I prevent chipping or splintering on teak ribs when cutting the second side of a trivet?

-

01:18:18 - Tim: What is a time-saving strategy for a large-scale production operator cutting different patterns on every sheet?

Keywords:

cnc calibration, rest machining, boundary offset, match fit system, vector validator, rotary axis troubleshooting, wood inlay tips, teak tear-out, compression bits, cabinetry production, vcarve pro, aspire

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!