Master Workholding & Profile Toolpaths + Special Announcement

📰Weekly Recap Newsletter

9/21/2024

Welcome to this week's edition of our CNC Weekly Recap. As we transition into fall, it's the perfect time to refine our CNC skills and tackle those indoor projects. This week, we're exploring an essential aspect of CNC machining that can make or break your projects - workholding. We'll also dive into a versatile and powerful Vectric toolpath that every CNC enthusiast should master.

But before we get to that, I want to let you know that I'll be away for the next two weeks on my honeymoon. While I'm off on a cruise exploring Northern Europe with my wife, Bella, I wanted to make sure you're all set with some exciting CNC opportunities and reminders.

🌟 Special Announcement

I'll be away from 9/24/2024 to 10/7/2024, which means there won't be any new newsletters or regular live lessons during this time. But don't worry, we've got something special lined up for you!

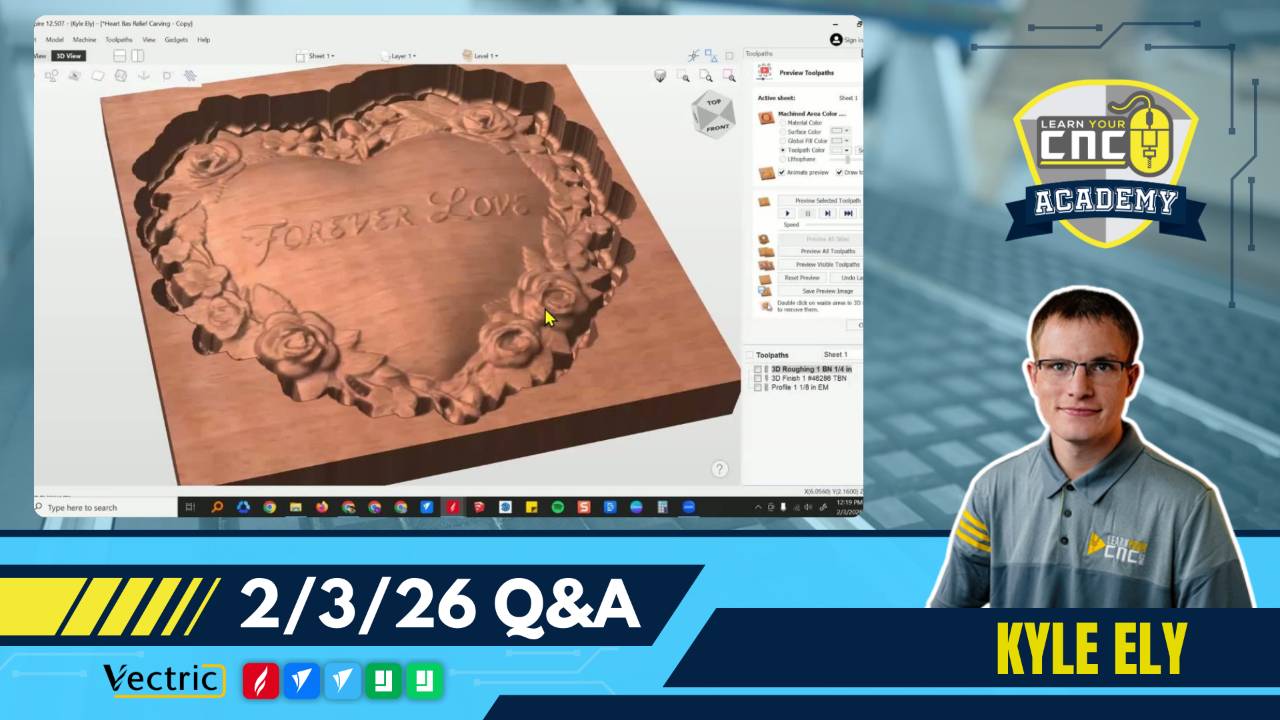

🎙️ Special Vectric Q&A Meetup

Date: Thursday, 9/26/2024

Time: 12pm EST

Host: Robert Sandstrom from Rob Sandstrom Designs

Rob, one of our talented students, will be stepping in to host a special Q&A session. He's a master of epoxy inlay projects and has been exploring AI tools for CNC projects. This is a fantastic opportunity to dive into these exciting topics!

⚠️ Important: This Q&A will use a different Zoom link than usual. Please check the Meetup page on our community site for the correct link.

🏆 September Community Project Challenge Reminder

Don't forget about our ongoing September Community Project Challenge! This month, we're offering our biggest prizes ever!

Project Theme: Creating Stacked Text Signs with CNC

Deadline: 10/6/2024

Prizes:

- 🥇 1st Place: A fully licensed version of Aspire software donated by Vectric (valued at $2,000)

- 🥈 2nd Place: A free 1-hour 1:1 lesson with me, your expert Vectric instructor

- 🥉 3rd Place: A $30 gift card to IDC Woodcraft for CNC bits

Make sure to enter and showcase your creativity!

🛠CNC Troubleshooting Corner🛠

This Week's Focus:

Mastering Workholding Techniques

Proper workholding is crucial for achieving precise, high-quality results in your CNC projects. Let's explore some effective strategies to keep your workpiece secure:

Key Workholding Methods:

- T-Track and Clamps:

- Versatile and adjustable

- Great for irregular shapes

- Tip: Use sacrificial boards to prevent clamp marks

- Vacuum Tables:

- Ideal for flat materials

- Leaves no visible holding marks

- Caution: Ensure proper sealing for effective hold

- Double-Sided Tape:

- Quick and easy for small parts

- Reduces the need for tabs

- Remember: Choose appropriate tape strength for your material. This is the tape that I recommend and love to use.

- Custom Fixtures:

- Perfect for repeat jobs

- Ensures consistency across multiple parts

- Investment in time saves time in the long run

- Threaded Inserts:

- Secure odd-shaped parts

- Allows for easy flipping of workpieces

- Pro Tip: Use in combination with other methods for extra security

Pro Tip:

Always consider your workholding strategy during the design phase of your project. Planning ahead can save you time and headaches during machining. Don't forget to use Vectric's new Keep-out Zones feature (introduced in V12) to protect your clamps and fixtures!

Need More Help?

Join our weekly Q&A sessions or ask Spindle Sam for personalized troubleshooting advice!

(Not a member yet? Sign up here to join our community!)

📖CNC Term of the Week📖

Profile Toolpath

A Profile Toolpath in Vectric software is used to cut along the outside or inside of a vector shape, often to cut parts out of your material.

Key Features:

- Can cut on the inside, outside, or directly on the vector

- Allows for multiple depth passes

- Offers options for tabs to hold parts in place

- Can be used for both 2D and 3D projects

When to Use:

- Cutting out parts or shapes from your material

- Cutting along vector lines

- Engraving outlines

- Machining precise edges on your workpiece

Pro Tip:

When setting up a Profile Toolpath, pay attention to the "Do Separate Last Pass" setting. A small value (like 0.01") can leave material for a finishing pass, ensuring a clean, precise edge on your final cut.