Master Your Vectric Toolpaths: Raster vs Offset Strategies Explained

📰Weekly Recap Newsletter

9/15/2024

Welcome to another edition of our CNC Weekly Recap. This week, we're focusing on two fundamental toolpath strategies available in Vectric software: raster and offset. Understanding when and how to use these strategies can significantly impact your project's efficiency and quality. Let's dive in and explore how to make the most of these powerful Vectric features!

🛠CNC Troubleshooting Corner🛠

This Week's Focus:

Raster vs Offset Toolpaths in Vectric Software

Choosing between raster and offset toolpaths can greatly affect your project's outcome. Let's break down these strategies:

Raster Toolpath:

- Description: Cuts in parallel lines across the workpiece, similar to mowing a lawn.

- Best for: Large area clearance, surfacing, and 3D relief carving.

- Advantages:

- Consistent cutting direction

- Good for maintaining even tool wear

- Effective for complex 3D shapes

- Considerations:

- Can leave visible scan lines

- May require climb and conventional cutting

Offset Toolpath:

- Description: Follows the contour of the shape, working from the outside in or inside out.

- Best for: Pockets, profiles, and 2D designs.

- Advantages:

- Smooth finish on edges

- Maintains consistent climb or conventional cutting

- Efficient for shaped pockets

- Considerations:

- Can leave a small central core in some shapes

- May not be ideal for large flat areas

- Can leave visible toolpath marks

Pro Tip:

Mastering Vectric toolpaths is a journey of continual learning and experimentation. Don't hesitate to test different approaches on scrap material to see what works best for your specific projects and setup.

Need More Help?

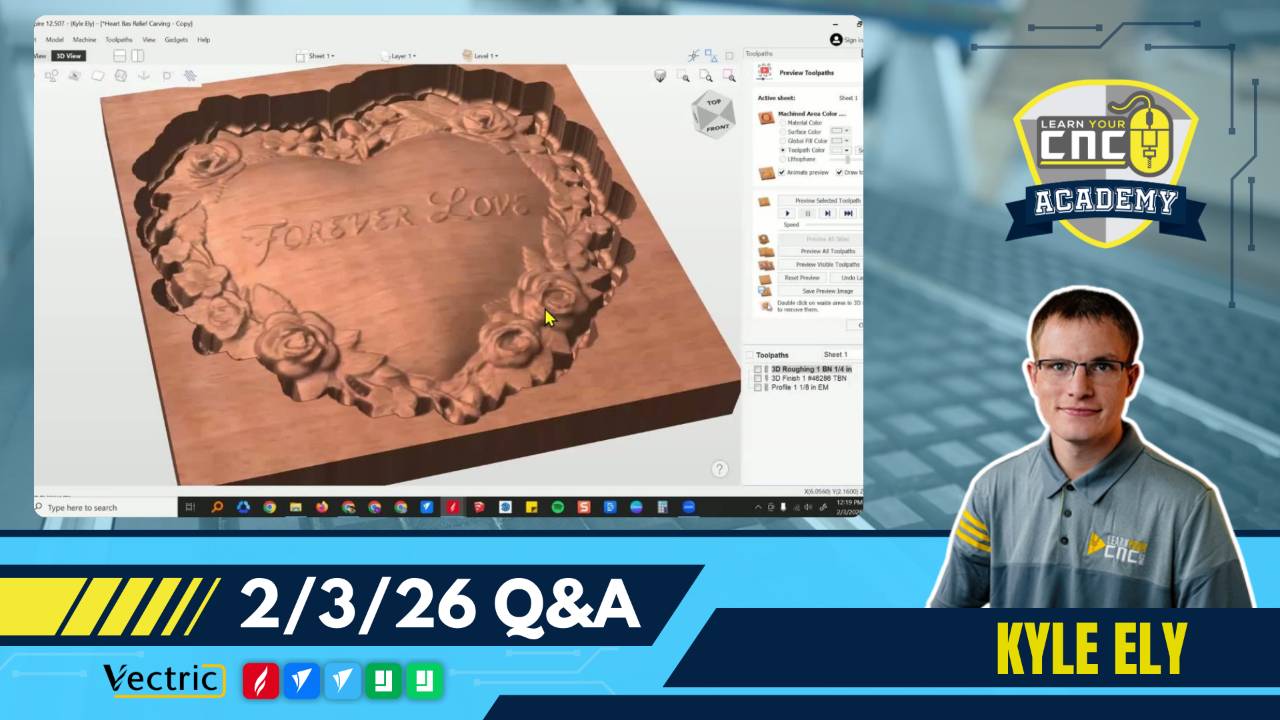

Join our weekly Q&A sessions or ask Spindle Sam for personalized troubleshooting advice!

(Not a member yet? Sign up here to join our community!)

📖CNC Term of the Week📖

Pocket Toolpath

In Vectric software, a pocket toolpath is used to remove material from the inside of a closed shape, creating a recess or "pocket" in the workpiece.

Key Features:

- Can use both raster and offset cutting patterns

- Allows for multiple depth passes

- Offers options for dealing with islands (internal features)

When to Use:

- Creating recessed areas in signs

- Forming cavities for inlays

- Machining component fittings

- General material removal within a defined boundary

- Surfacing your spoilboard

Pro Tip:

When setting up a pocket toolpath, pay close attention to the "Pocket Allowance" setting. A small negative value can ensure clean vertical edges, while a positive value will leave some material for a finishing pass.