New in Vectric V12: Master Keep-out Zones & Safe Z Heights

📰Weekly Recap Newsletter

8/31/2024

This week, we're diving into an exciting new feature in Vectric V12 that could save you from costly mistakes and damaged tools. We'll also explore a crucial concept that goes hand-in-hand with this new feature. Whether you're a seasoned pro or just starting out, these insights will help you work smarter and safer with your CNC machine.

Let's jump into the world of smart CNC operations!

🛠CNC Troubleshooting Corner🛠

This Week's Feature:

Keep-out Zones in Vectric V12

Have you ever had that heart-stopping moment when your CNC tool comes dangerously close to a clamp or something else in the way? The new Keep-out Zone feature in Vectric V12 is here to put those worries to rest!

What are Keep-out Zones?

Keep-out Zones are defined areas of your material where it's unsafe for a tool to pass through or over. They represent obstacles like clamps or screws that protrude above the material surface.

How to Use Keep-out Zones:

- Create closed vectors around areas to avoid

- Select these vectors when setting up your Keep-out Zones

- Vectric will automatically plan toolpath routes to avoid these zones

Key Benefits:

- Prevents tool collisions with hold-downs

- Reduces risk of project damage

- Allows for more confident automated operations

Pro Tip:

When setting up Keep-out Zones, always err on the side of caution. Make your zones slightly larger than the actual obstacle to account for tool diameter and any potential vibration or movement during cutting.

Need More Help?

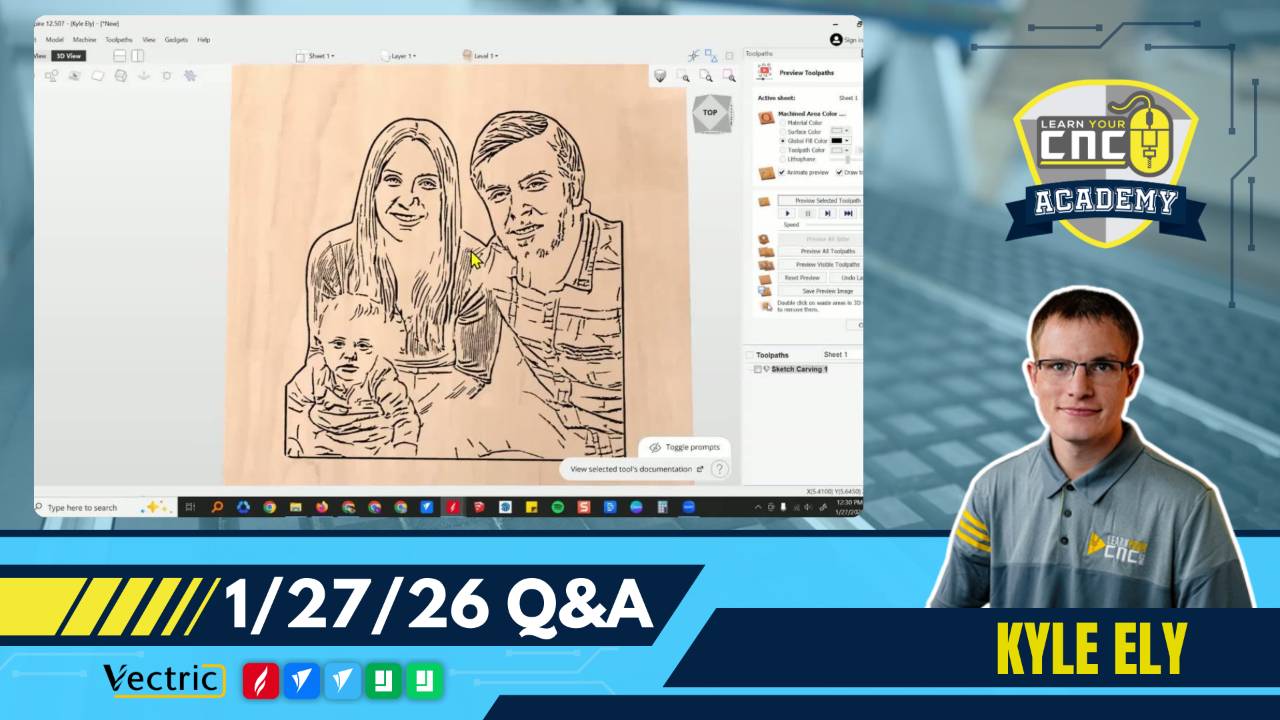

Join our weekly Q&A sessions or ask Spindle Sam for personalized troubleshooting advice!

(Not a member yet? Sign up here to join our community!)

📖CNC Term of the Week📖

Safe Z Height: Rapid Z Gap vs Home Z Gap

Understanding Safe Z Heights is crucial for efficient and safe CNC operations, especially when using features like Keep-out Zones.

Rapid Z Gaps:

- Definition: The height above the material at which it's safe for the cutter to move at rapid or maximum feed rate.

- Usage: Used for movements between toolpaths within a job.

- Setting: Found in the Material Setup form as "Rapid Z Gaps above Material".

Home/Start Z Gap:

- Definition: The absolute position where the tool starts from and returns to at the end of the job.

- Usage: Used for the initial and final tool movements, often called the "park position".

- Setting: Found in the Material Setup form as "Z Gap Above Material".

Key Differences:

- Rapid Z Gap is used during the job, Home Z Gap is used before and after.

Pro Tip:

Always set your Home Z Gap high enough to clear all obstacles on your machine bed, including clamps and Keep-out Zones. This ensures safe movement to and from the park position. Also, to get more efficient toolpath machining times, do not set your rapid Z gaps too high, as that will create a lot of unnecessary movements.