Tool Breakage Solutions & Stepover Secrets Revealed

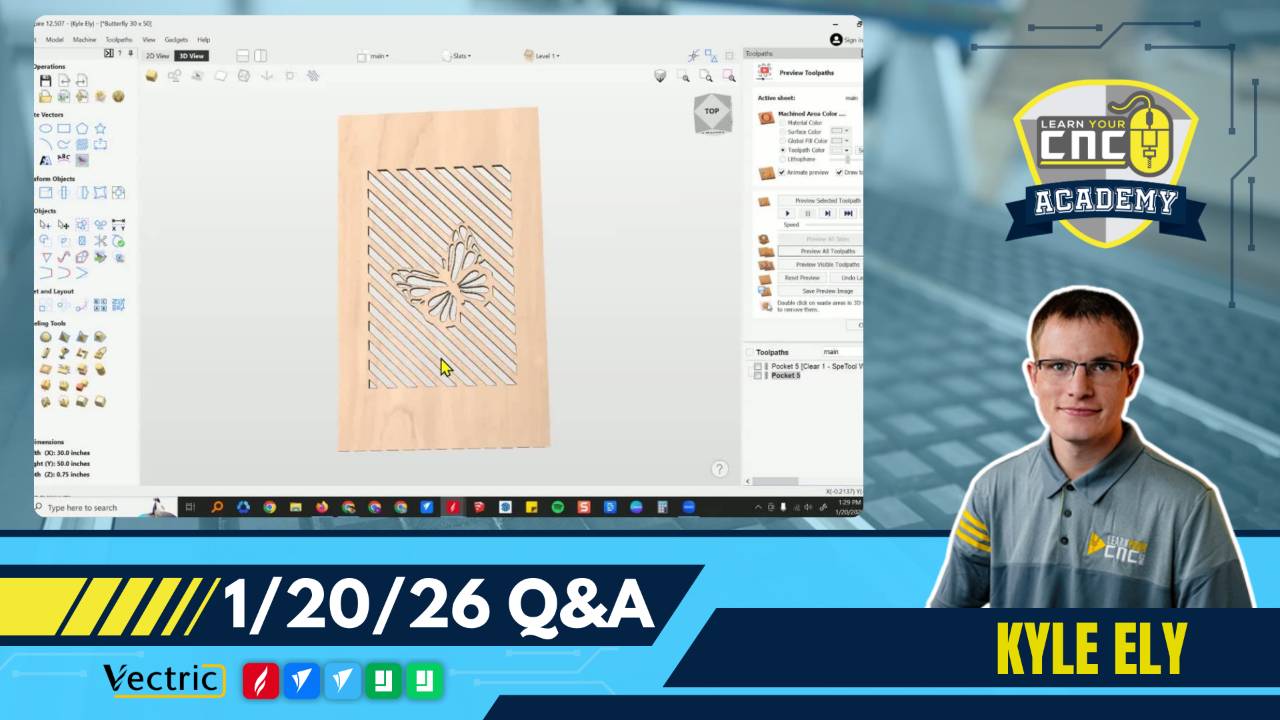

📰Weekly Recap Newsletter6/29/2024 Welcome back to our "Weekly Recap Newsletter"! We're thrilled to see the positive response to our first edition. Your enthusiasm fuels our commitment to bringing you the most valuable CNC insights and community highlights each week. In this edition, we've got some exciting project showcases, a crucial troubleshooting tip, and a deep dive into an essential CNC term. Whether you're fine-tuning your skills or tackling a new challenge, we've got something for you. Let's jump into this week's CNC adventure! 🛠CNC Troubleshooting Corner🛠This Week's Issue: Tool Breakage During CuttingYou're in the middle of a project, and suddenly your cutting tool snaps, potentially ruining your workpiece and causing a safety hazard. Possible Causes:

Quick Fix:

Pro Tip:Listen to your machine! Unusual sounds or vibrations often precede tool breakage. If something doesn't sound right, stop the machine and investigate immediately. Need More Help?Join our weekly Q&A sessions or ask Spindle Sam for personalized troubleshooting advice! (Not a member yet? Sign up here to join our community!) 📖CNC Term of the Week📖StepoverDefinition: Stepover, also known as "step-over" or "width of cut," refers to the distance the tool moves laterally between parallel toolpaths when cutting or milling a surface. It's typically expressed as a percentage of the tool's diameter. Why it matters: The stepover value affects both the quality of your finished surface and the efficiency of your cutting process. A smaller stepover produces a smoother surface finish but takes longer to complete, while a larger stepover is faster but may leave visible toolpath marks. Example: If you're using a 1/4" (6.35mm) end mill and set a 50% stepover, the tool will move laterally by 1/8" (3.175mm) between parallel passes. Tip: For roughing operations, a stepover of 40% to 75% of the tool diameter is common. For finishing passes with ball nose bits, consider using a stepover of 8% to 10% for smoother results. 👇This Week's Highlights👇 Must-Know CNC Tricks + Time-Sensitive Updates!

Must-Know CNC Tricks + Time-Sensitive Updates!

📰Weekly Recap Newsletter

12/1/2024

Happy December! Get ready to elevate your CNC game with the latest tips, tricks, and inspiration from the Learn Your CNC Academy. From tackling common carving challenges to crafting stunning fall-themed projects, we’ve packed this edition with everything you need to stay ahead.

⚠️ Time-Sensitive Info! Don’t miss our biggest sale of the year—30% off Vectric Tra...

Say Goodbye to Toolpath Marks - Must-Know CNC Toolpath Tips!

Say Goodbye to Toolpath Marks - Must-Know CNC Toolpath Tips!

📰Weekly Recap Newsletter

11/17/2024

We’re back with another exciting edition of the Learn Your CNC Academy newsletter, packed with everything you need to level up your CNC game. This week, we’re diving into must-know troubleshooting tips, showcasing incredible student projects, and shining the spotlight on our Project Challenge of the Month.

Whether you’re here for step-by-step lessons, practic...

Master Workholding & Profile Toolpaths + Special Announcement

Master Workholding & Profile Toolpaths + Special Announcement

📰Weekly Recap Newsletter

9/21/2024

Welcome to this week's edition of our CNC Weekly Recap. As we transition into fall, it's the perfect time to refine our CNC skills and tackle those indoor projects. This week, we're exploring an essential aspect of CNC machining that can make or break your projects - workholding. We'll also dive into a versatile and powerful Vectric toolpath that every CNC ent...

|