12-09-2025 Q&A: Scroll Corbels, 3D Photo Carving Optimization, and Rotary Tapered Cylinders

Dec 09, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

In this Q&A session, we discussed strategies for complex 3D projects, including carving four-sided scroll corbels and optimizing 3D photo carvings from Easy Carve by adjusting bit selection and stepover settings. We also covered troubleshooting dimensional inaccuracies in inlay plugs, techniques for creating tapered cylinders on a rotary axis, and how to correctly configure the Rounding Gadget for turned blanks. Additionally, we reviewed tips for using sacrificial spoilboards to achieve sharp edges on sloped 3D profiles.

Key Tips Learned in this Q&A:

-

Creating Sharp Edges on Sloped 3D Parts: When using a ball nose bit on a sloped profile (like a hexagon or octagon side), the bit's radius often leaves a small "lip" at the bottom. To get a sharp edge, use a sacrificial spoilboard on top of your machine bed, extend your vectors, and cut slightly deeper (e.g., 1/8") to force the radius into the waste material.

-

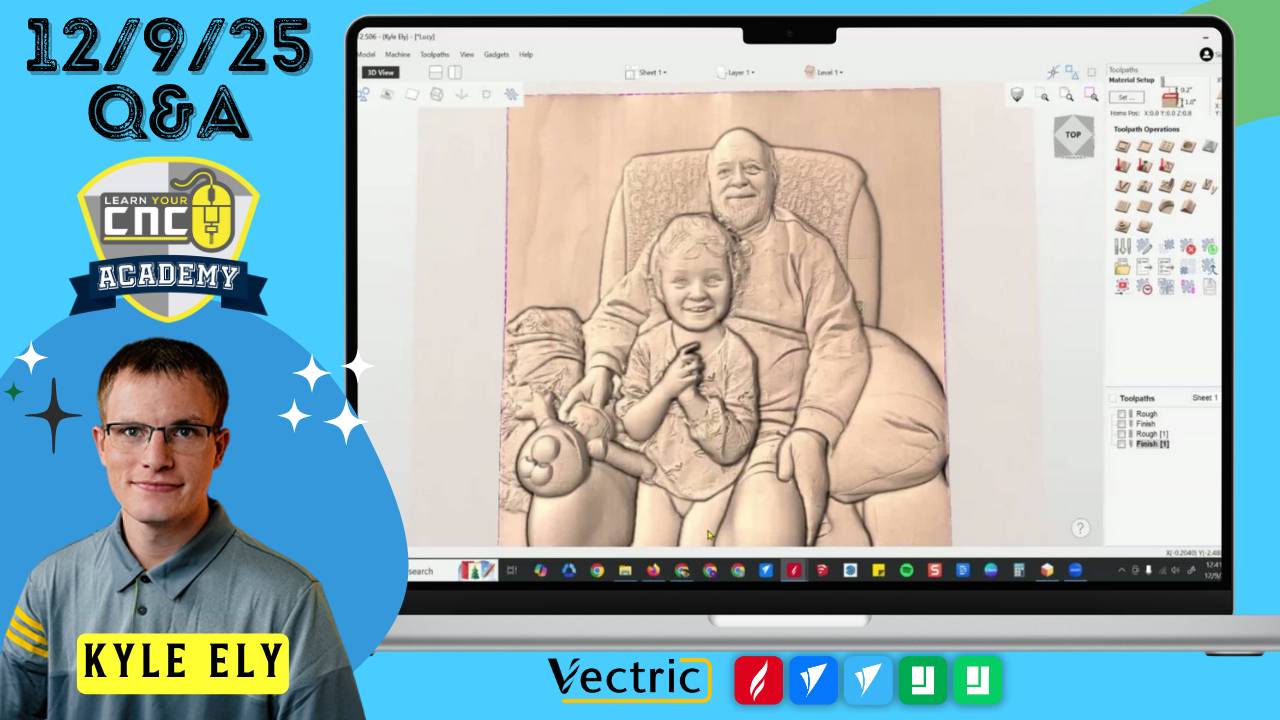

Optimizing 3D Photo Carves: To improve the detail on 3D photo carvings (like those from Easy Carve), reduce the stepover on your finishing pass to 8-12%. To counter the increased machining time, you can significantly increase the feed rate (e.g., up to 300 ipm) if your machine allows, as 3D moves rarely reach full speed anyway. Also, remove unnecessary boundary offsets to save time.

-

Rotary Tapering Strategy: To carve a design (like a V-groove) onto a tapered cylinder on a rotary axis, you must first create a 3D model of the taper itself (using a two-rail sweep in Aspire is best). Once the tapered model exists, use the "Project toolpath onto 3D model" feature to ensure the cut follows the slope.

-

Rounding Gadget Configuration: When using the Rounding Gadget to true up a blank, ensure you input your desired final diameter in the job setup/diameter field, and the starting rough diameter in the "Blank Size" field within the gadget. Reversing these will cause errors.

-

VCarve Inlay Bit Selection: For VCarve inlays, it is generally recommended to start with a V-bit rather than a tapered ball nose for easier setup. For the clearance tool, use an up-cut bit to evacuate chips effectively, as the V-bit will clean up the final edges.

Questions Answered in this Q&A:

-

00:04:29 - Jeff: How do I go about carving four-sided scroll corbels? Is there a lesson for this?

-

00:09:20 - Ruth: How can I get a squared bottom edge on a sloped side (octagon/hexagon) when the ball nose bit leaves a radius lip?

-

00:18:19 - Joe: I'm using Easy Carve for a photo. How do I choose the best tapered ball nose bit and settings to get high resolution without excessive cut times?

-

00:38:53 - Randy: My charcuterie board plugs are machining slightly smaller (0.403") than the design (0.44"). Is this runout or tramming?

-

00:45:22 - Ron: I am trying to carve Panel 28 III from clipart but can't seem to get it right.

-

00:47:54 - Ray: Why are tools in the tool settings frozen/grayed out in Vectric 12.5? Also, can I downsize a digital file and still carve it?

-

00:52:42 - Carl: For inlays, do you prefer a V-bit or tapered ball nose? And which clearance bit (up/down/compression) is best?

-

00:55:25 - Dustin: How do I cut points/V-grooves on a tapered cylinder (like a pool cue) on a rotary axis?

-

01:03:49 - Thomas: I don't see the "Copy Prompt" option in Easy Create history. Also, tip: TIFF files from Easy Create work well in LightBurn.

-

01:10:10 - Dick: Sharing results of using AI/Easy Create to create 3D files of real locations (Mt. Washington).

-

01:12:26 - James: I'm making a double-sided box with a dome on top. Where is the remainder of the box in relation to the component?

-

01:15:05 - Ray: My toolpath preview shows 7 minutes for clearance but 5 hours for the 30-degree V-bit. Is this normal?

-

01:17:11 - Mark: How can I create a simple half-inch radius on the back of a concrete mold using the molding toolpath?

-

01:21:27 - Alfred: I'm getting "value too large" errors with the Rounding Gadget when trying to turn a lathe-rounded blank to a specific diameter.

Keywords:

scroll corbels, 3d carving, tapered ball nose, stepover, molding toolpath, rotary axis, tapered cylinder, rounding gadget, easy create, vectric aspire, vcarve inlay, toolpath efficiency, machine tramming, lightburn, topographical maps

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!