CNC Power Recovery Tips & Nesting Techniques Explained

📰Weekly Recap Newsletter

8/24/2024

I hope this newsletter finds you well and busy with exciting projects! This week, we're tackling a challenge that many of us have faced at one point or another - unexpected interruptions during a carve. We'll also dive into a powerful feature available in some Vectric software versions that can significantly boost your material efficiency.

Let's dive into this week's CNC insights!

🛠CNC Troubleshooting Corner🛠

This Week's Issue: Recovering a Carve After a Power Outage or Failure

We've all been there - you're in the middle of a crucial project when suddenly, the power goes out or your machine stops unexpectedly. Don't panic! There are ways to salvage your work and complete your project successfully.

Key Steps for Recovery:

- Assess the situation: Determine the cause of the interruption.

- Secure the workpiece: Ensure it hasn't shifted during the unexpected stop.

- Re-home your machine: Carefully re-establish your machine's reference points.

- Adjust your G-code: Modify your code to resume from the point of interruption. (See video below)

- Test on scrap material: If possible, test your recovery process on a similar piece before continuing on your actual project.

For a detailed walkthrough of this process, check out my YouTube video on the subject:

|

Pro Tip:

Consider investing in a UPS (Uninterruptible Power Supply) for your CNC setup. It can provide temporary power during short outages and protect your equipment from electrical issues.

Need More Help?

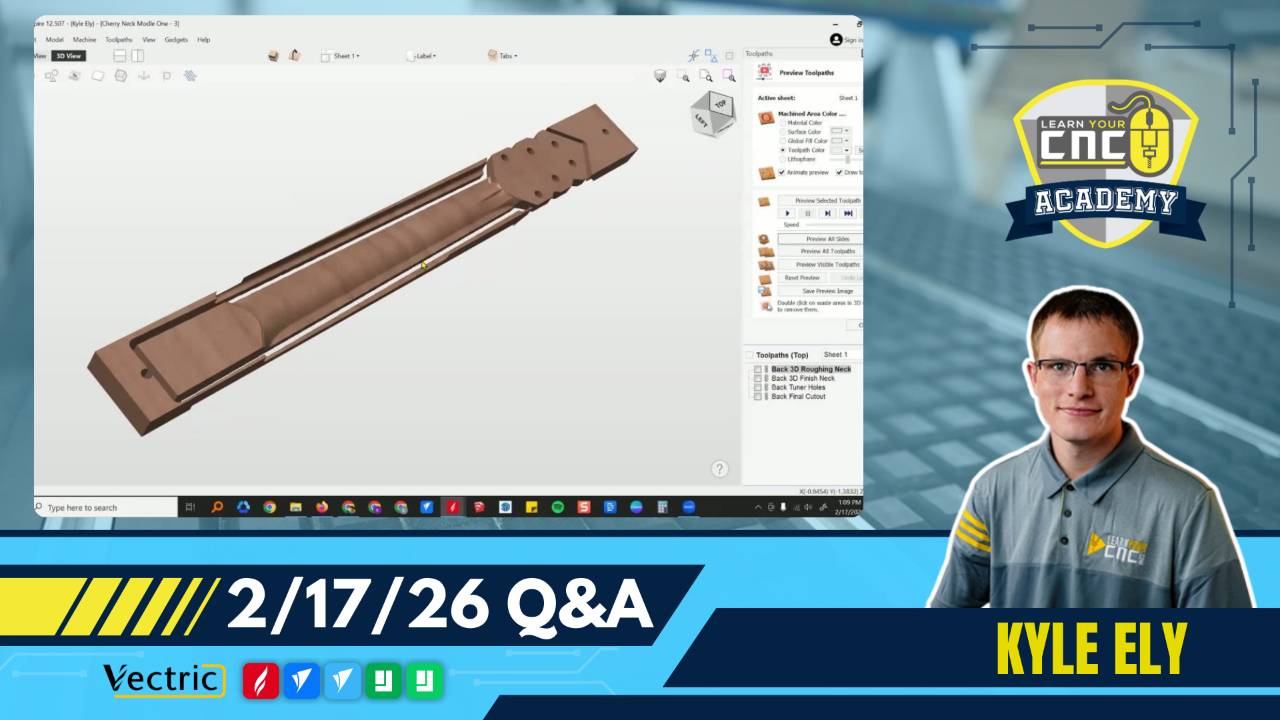

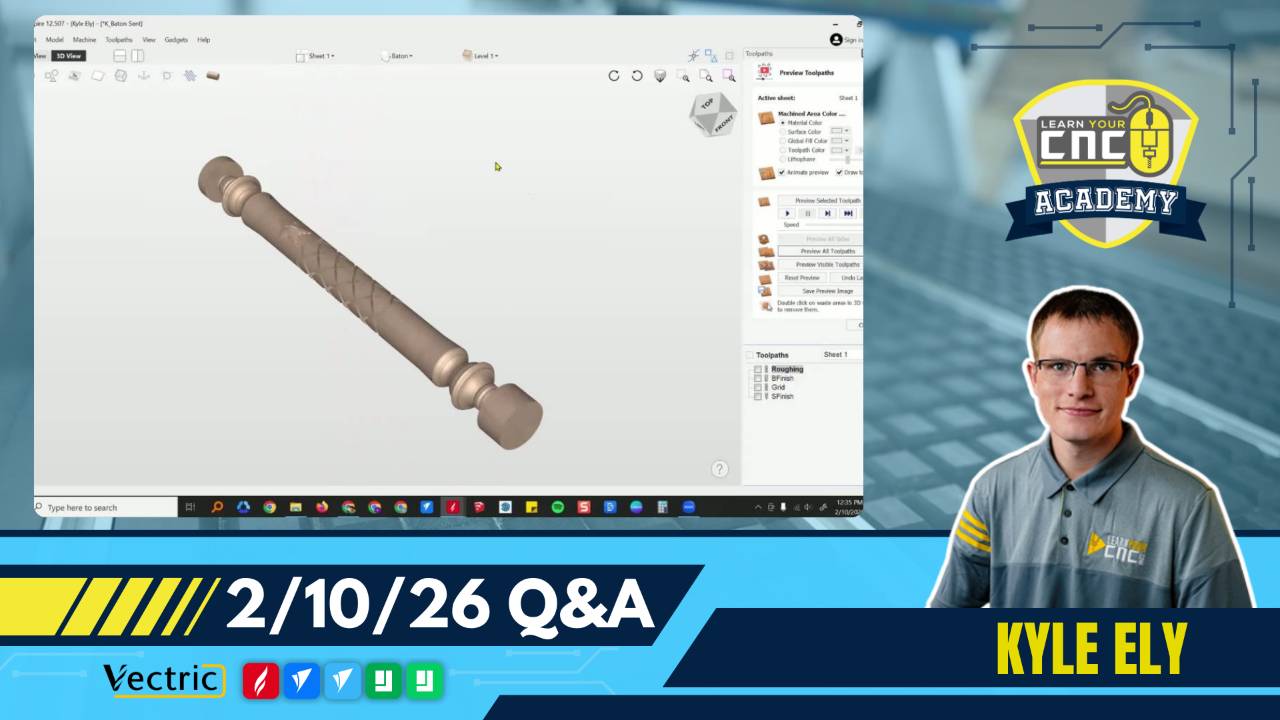

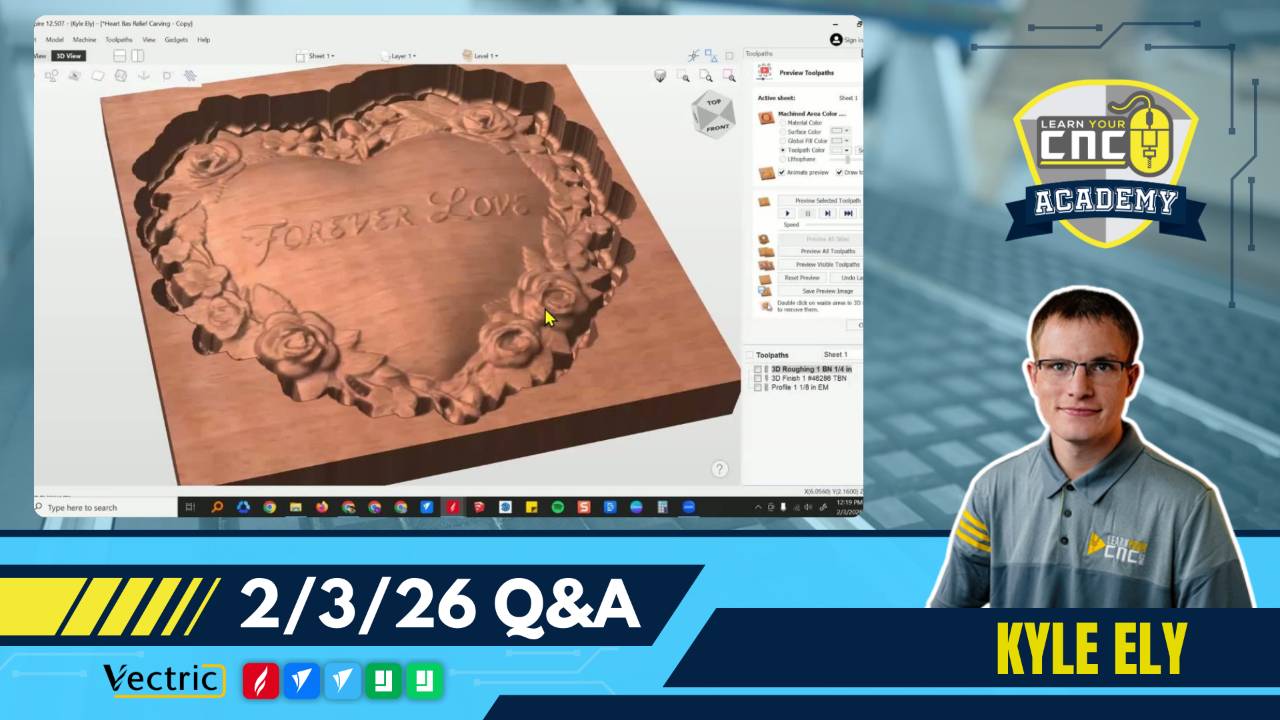

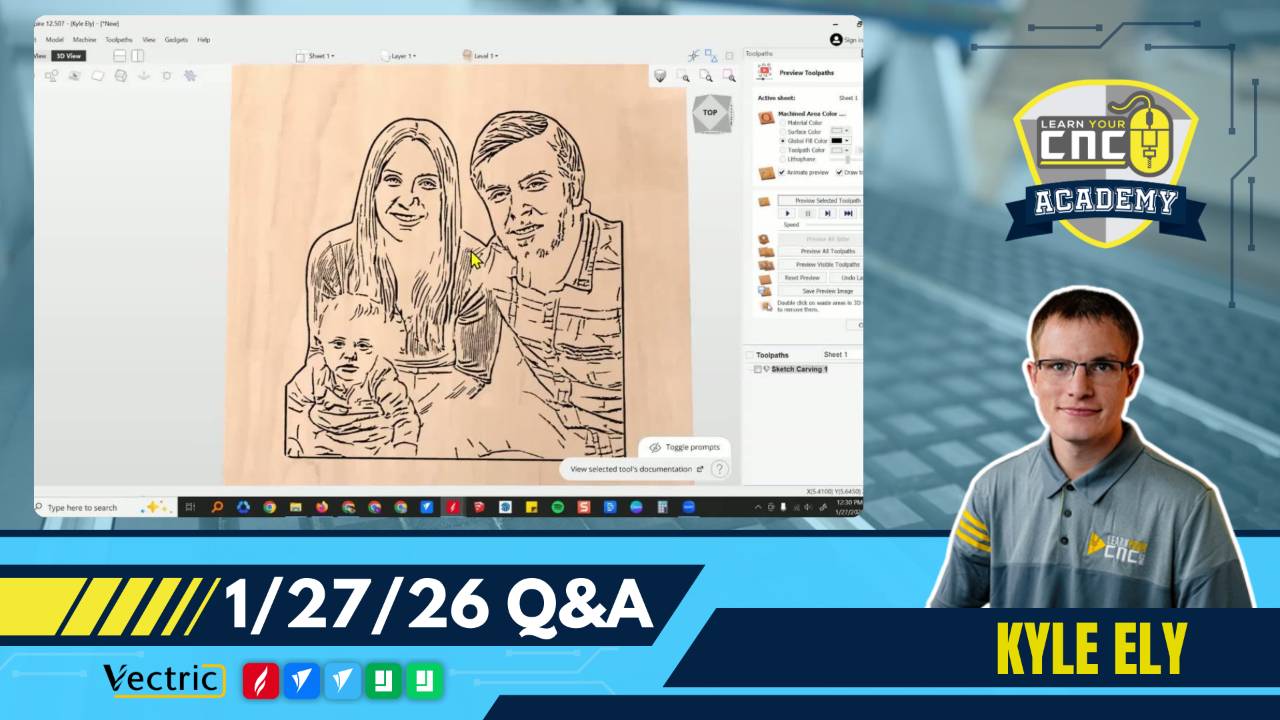

Join our weekly Q&A sessions or ask Spindle Sam for personalized troubleshooting advice!

(Not a member yet? Sign up here to join our community!)

📖CNC Term of the Week📖

Nesting

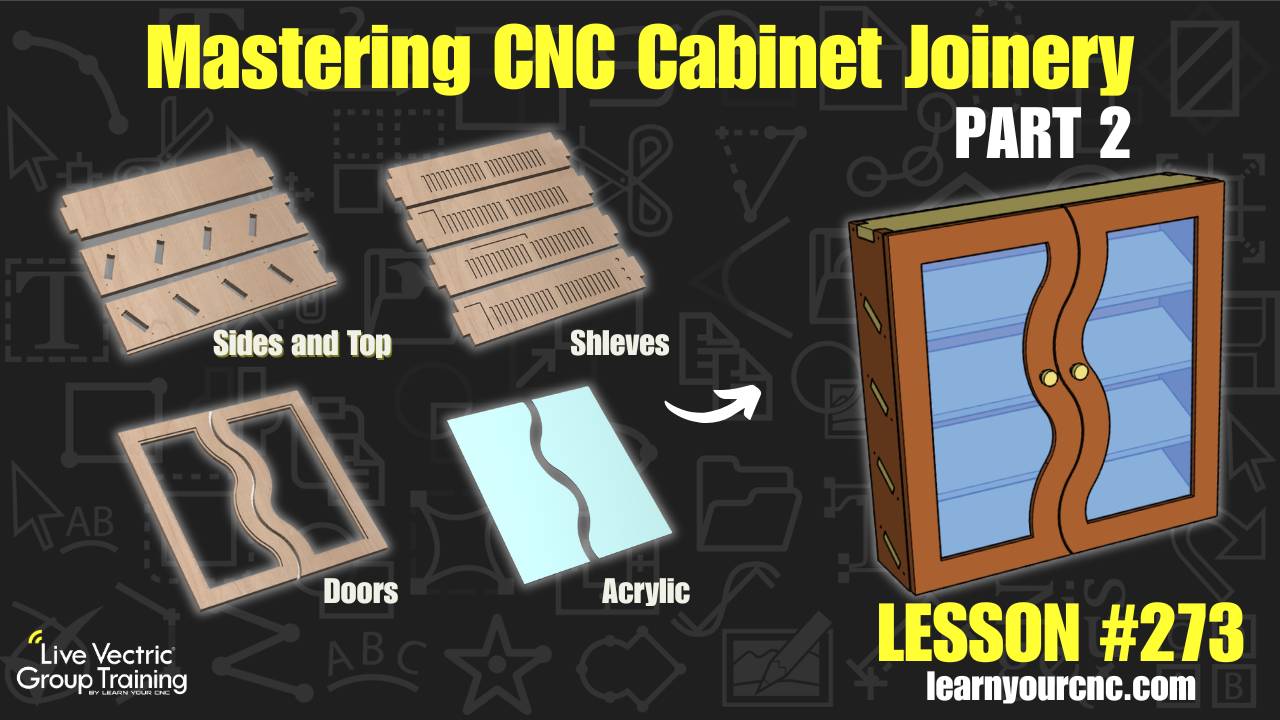

Definition: Nesting is the process of efficiently arranging multiple parts on a single sheet of material to minimize waste. It's a powerful feature available in Aspire, VCarve Pro, Cut2D Pro, and some other CAD/CAM software (note: it's not available in Cut2D Desktop or VCarve Desktop).

Why it matters:

- Maximizes material usage

- Reduces waste and costs

- Increases production efficiency

- Optimizes cutting time

Key Nesting Considerations:

- Part orientation and rotation

- Material grain direction

- Spacing between parts

- Tool path strategies

Tip: When nesting, consider the order of operations. Arrange parts so that smaller, more delicate pieces are cut before larger, more stable ones. This can help prevent movement or damage during the cutting process.