A Heartfelt Thank You & This Week's CNC Insights

📰Weekly Recap Newsletter

8/17/2024

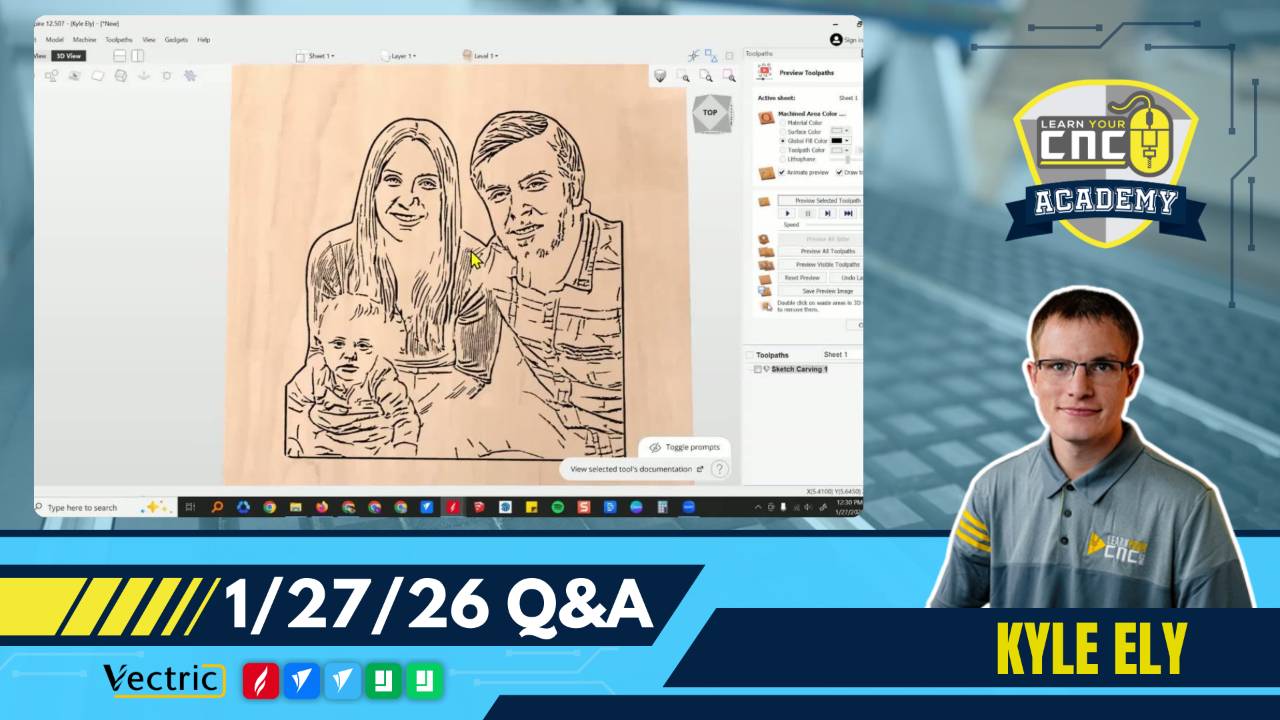

A Special Thank You from the Newlyweds!🤵👰

Dear CNC Family,

I'm overwhelmed with gratitude for the outpouring of love and congratulations from our amazing CNC community. Your kind words and well-wishes have made this special time even more memorable for Bella and me.

As you can see, it was a magical day filled with joy, love, and new beginnings. Your support means the world to us, and we're touched to have such a wonderful extended family in the CNC community.

Now, as we embark on this new chapter, I'm excited to dive back into the world of CNC with renewed energy and inspiration.

Let's get back to our regular programming, shall we?

🛠CNC Troubleshooting Corner🛠

This Week's Issue: Minimizing Tearout in Wood Projects

Are you frustrated with rough edges and splintering when cutting wood on your CNC? Tearout can be a real project-ruiner, but fear not! We've got some tips to help you achieve clean, crisp cuts.

Key Strategies:

- Use sharp, high-quality bits

- Make sure to use the correct up/down/compression flutes

- Optimize your feed rate and spindle speed

- Consider climb cutting for finish passes

- Use sacrificial backing boards

- Apply tape to the cutting area

Pro Tip:

For intricate designs or text, try a two-stage cutting process. First, use a larger bit to rough out the shape, leaving a small amount of material. Then, switch to a smaller bit for a finishing pass. This method can significantly reduce tearout and improve overall quality.

Need More Help?

Join our weekly Q&A sessions or ask Spindle Sam for personalized troubleshooting advice!

(Not a member yet? Sign up here to join our community!)

📖CNC Term of the Week📖

Chip Load

Definition: Chip load refers to the amount of material removed by each cutting edge of a tool as it rotates. It's typically measured in inches per tooth (IPT) or millimeters per tooth (MMT).

Why it matters:

- Affects tool life and cutting efficiency

- Influences surface finish quality

- Impacts heat generation during cutting

Calculating Feed Rate:

Chip Load = Feed Rate / (RPM × Number of Flutes)

Not sure what all of those mean?

- Feed Rate: Speed at which the tool moves through the material

- RPM: Rotational speed of the tool

- Number of Flutes: The number of cutting edges on your tool

Tip: Different materials and tools have optimal chip load ranges. Consult manufacturer recommendations and experiment carefully to find the sweet spot for your specific applications.