Master Vectric Resizing Techniques & Optimize Your Cutting Depth

📰Weekly Recap Newsletter

7/27/2024

Welcome to this week's edition of the Learn Your CNC Academy Newsletter. We're thrilled to announce some exciting updates to enhance your newsletter experience!

🎉 New and Improved Format: We've refreshed our newsletter layout to make it even more engaging and informative. You'll still find all the CNC wisdom you love, now in a more streamlined and easy-to-read format.

📚 Access to Past Newsletters: Miss a week? No problem! You can now review all our past newsletters at your convenience. It's a treasure trove of CNC knowledge at your fingertips. (We are adding past newsletters now, so stay tuned for those.)

💬 Join the Conversation: We value your thoughts and experiences. You can now comment on newsletters, share your insights, and connect with fellow CNC enthusiasts. Your voice matters in our community!

Check out our new newsletter hub here: https://academy.learnyourcnc.com/newsletters/lycnc-weekly-newsletter

We're excited about these changes and can't wait to hear what you think. Now, let's dive into this week's CNC insights!

🛠CNC Troubleshooting Corner🛠

This Week's Issue: Resizing Multiple Objects in Vectric Software

Have you ever created an array of shapes in your CNC design, only to realize they're not quite the right size? We've got you covered!

We've posted a quick tip video on our YouTube channel that walks you through two effective methods to resize multiple elements in your design:

- Adjusting the pocket allowance in your toolpath settings

- Using the scale tool to resize vector shapes

These techniques can save you time and frustration when you need to make adjustments to your project.

Check out the full video here:

|

Pro Tip:

When using the scale tool, remember to use the "Scale items individually" option and set the anchor point to the center to maintain the layout of your array. This allows you to precisely control the size of each element while keeping their positions intact. (watch the video above to learn more)

Need More Help?

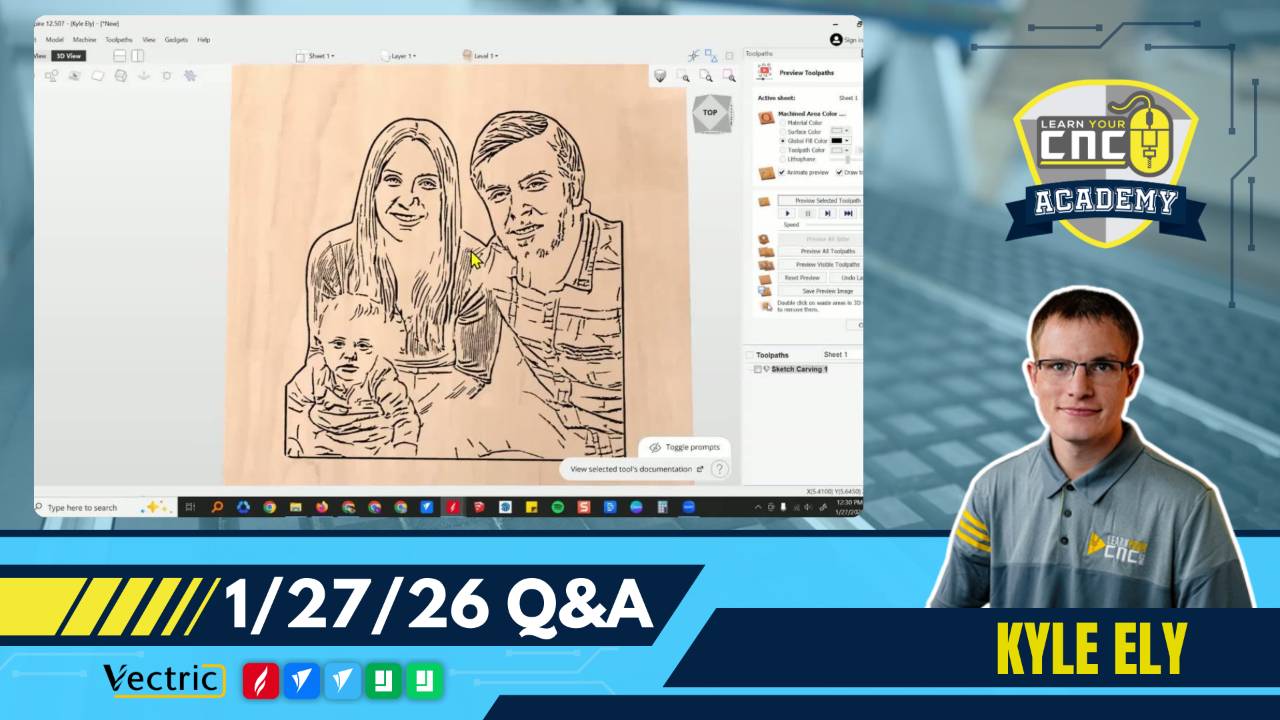

Join our weekly Q&A sessions or ask Spindle Sam for personalized troubleshooting advice!

(Not a member yet? Sign up here to join our community!)

📖CNC Term of the Week📖

Depth Per Pass

Definition: Depth Per Pass, also known as Depth of Cut (DOC) or Step Down, refers to the distance the cutting tool moves into the material in each vertical step or layer during a CNC machining operation.

Why it matters: The Depth Per Pass is a critical parameter that affects:

- Cutting forces and tool wear

- Surface finish quality

- Machining time and efficiency

- Heat generation in the cutting process

Choosing the right Depth Per Pass:

-

Shallower passes generally result in better surface finish and less tool wear, but increase machining time.

-

Deeper passes can speed up the machining process but may lead to increased tool wear and potential for chatter.

-

The optimal Depth Per Pass depends on factors like material hardness, tool diameter, machine rigidity, and desired surface finish.

Typical ranges:

-

Roughing operations: 30-50% of tool diameter

-

Finishing operations: 5-15% of tool diameter

Tip: When working with new materials or tools, start with conservative Depth Per Pass settings and gradually increase them while monitoring cut quality, tool wear, and machine performance. This approach helps you find the optimal balance between efficiency and quality for your specific setup..