Maximize Spindle Life & Unlock the Power of Pocketing

📰Weekly Recap Newsletter

7/20/2024

In today's edition, we're focusing on a critical component of your CNC machine - the spindle. We'll share tips to keep it running smoothly for years to come. Plus, we're diving into a versatile machining strategy that can elevate your projects to new levels of efficiency and precision.

So, let's power up and dive into this week's CNC insights!

🛠CNC Troubleshooting Corner🛠

This Week's Issue: Premature Spindle Wear

|

(Not a member yet? Sign up here to join our community!)

📖CNC Term of the Week📖

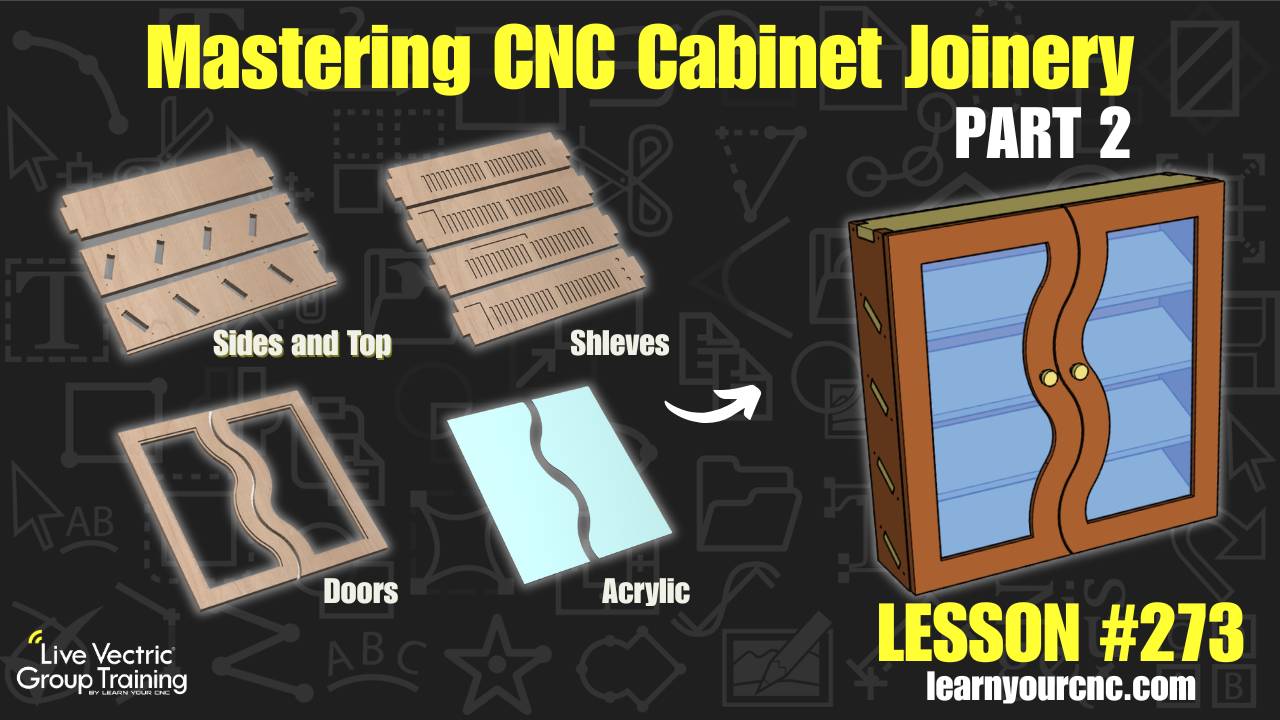

Pocketing

Definition: Pocketing is a CNC machining operation used to remove material from the interior of a part, creating a recessed area or "pocket" in the workpiece.

Why it matters: Pocketing is a fundamental technique in CNC machining, used in a wide variety of applications from creating cavities for inlays to reducing the weight of a part. Efficient pocketing strategies can significantly reduce machining time and improve part quality.

Key Concepts:

-

Roughing: Initial material removal, often using larger tools and more aggressive cutting parameters (stepover and depth per pass).

-

Finishing: Final passes to achieve the desired surface finish and dimensional accuracy.

-

Tool Path Strategies: Various patterns like offset or raster clearing can be used depending on the pocket shape and desired outcome.

When to use:

-

Creating recesses for inlays or mounting points

-

Weight reduction in parts

-

Forming complex internal features

Tip: When designing pockets, consider using filleted corners instead of sharp internal corners. This allows for the use of larger tools, reducing machining time and improving tool life. For deep pockets, consider a "stair-step" approach, gradually increasing the depth with each pass to maintain tool rigidity and improve chip evacuation.