09-02-2025 Q&A: Vector Cleanup, Rotary STL Import, Logo Sign Toolpaths, Alignment Pins, and Fixing 3D Model Overlaps

Sep 02, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

In this Q&A session, we explored practical solutions to common CNC challenges. Topics included cleaning up messy vectors using the Vectric Validator, handling STL imports for rotary and two-sided projects, optimizing toolpaths for logos and signs, strategies for alignment pin setups, and troubleshooting unexpected toolpath marks caused by overlapping components.

Key Tips Learned in this Q&A:

-

Vector Cleanup with Fit Curves: Using Fit Curves to Vectors with tolerances like 0.01 or 0.1 can dramatically reduce intersections and overlaps, sometimes eliminating the need to manually edit hundreds of nodes.

-

Rotary vs. Two-Sided STL Import: When importing full-round STL models (e.g., walking sticks), always check “Create both sides” if cutting two-sided. Rotary cutting is ideal, but two-sided toolpaths are a solid fallback if no rotary is available.

-

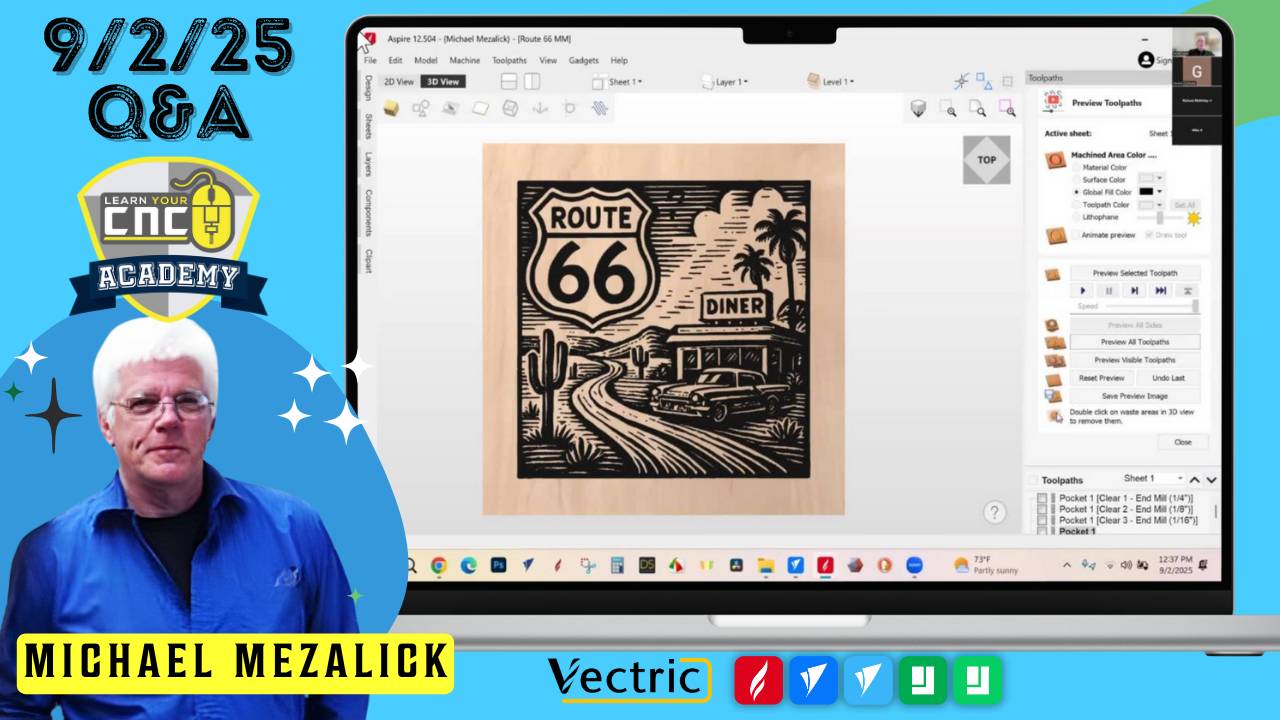

Logo & Sign Toolpath Efficiency: Illustrator vectors often import cleanly; using VCarve toolpaths with a clearance tool can reduce a 15-hour runtime to under 3 hours. V-bits can be more efficient than multiple small end mills.

-

Alignment Pins for Double-Sided Projects: Drill shallow alignment pockets in the material (not through-holes). Copy alignment vectors to the opposite side to generate spoilboard holes. Pins are for alignment only—not hold-down—so clamps are still required.

-

Troubleshooting 3D Model Artifacts: Extra ridges or marks in toolpaths often result from duplicate/overlapping components in the component tree. Removing the duplicate fixes the preview and machining output.

Questions Answered in this Q&A:

-

00:04:40 – How to handle vectors with lots of intersections from Vectric Validator?

-

00:15:21 – How to process an STL spiral walking stick for VCarve (Blender vs. native import)?

-

00:24:48 – Why is my logo sign taking 15+ hours and showing open vector errors?

-

00:29:44 – Why do some parts of my Route 66 sign design not appear in toolpaths?

-

00:34:34 – How do alignment holes and pins actually work for two-sided projects?

-

01:01:19 – What causes random toolpath lines/marks in a 3D carve, and how can they be removed?

Keywords:

vectric validator, vector cleanup, fit curves, overlaps, intersections, rotary stl import, walking stick stl, vcarve toolpaths, illustrator vectors, sign carving, runtime optimization, route 66 sign, alignment pins, double-sided cnc, spoilboard holes, japanese flush saw, 3d model overlap fix

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!