09-16-2025 Q&A: 3D Carving Details, Zero Planes, and Toolpath Efficiency

Sep 17, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

In this Q&A session, we covered strategies for improving detail in 3D carvings, clarified the differences between shape height and base height, and discussed when and why to use ball nose vs tapered ball nose bits. We also explored toolpath efficiency, rapid rates, zero planes as limit planes, snapping to guidelines, photo VCarve improvements, toolpath grouping, and vector drawing for guitars. The call wrapped up with tips for Aspire sculpting brushes and corner rounding tools.

Key Tips Learned in this Q&A:

-

3D Carving Detail: For faces or rounded features, use a ball nose (or tapered ball nose for strength at small sizes) instead of an end mill. Increasing shape height (not base height) can dramatically improve detail.

-

Toolpath Efficiency: Adjust stepover, depth per pass, and feed rates to significantly cut down roughing time. Verify machine rapid rates and acceleration settings for accurate carve-time estimates.

-

Base vs Shape Height: Shape height raises the surface detail; base height lifts the whole model. Tilt and fade options modify thickness and detail differently.

-

Zero Planes = Limit Planes: A zero plane (or adjusted cutting plane) prevents cutting below a set surface. It can be tilted, thickened, or multiplied to control carving depth.

-

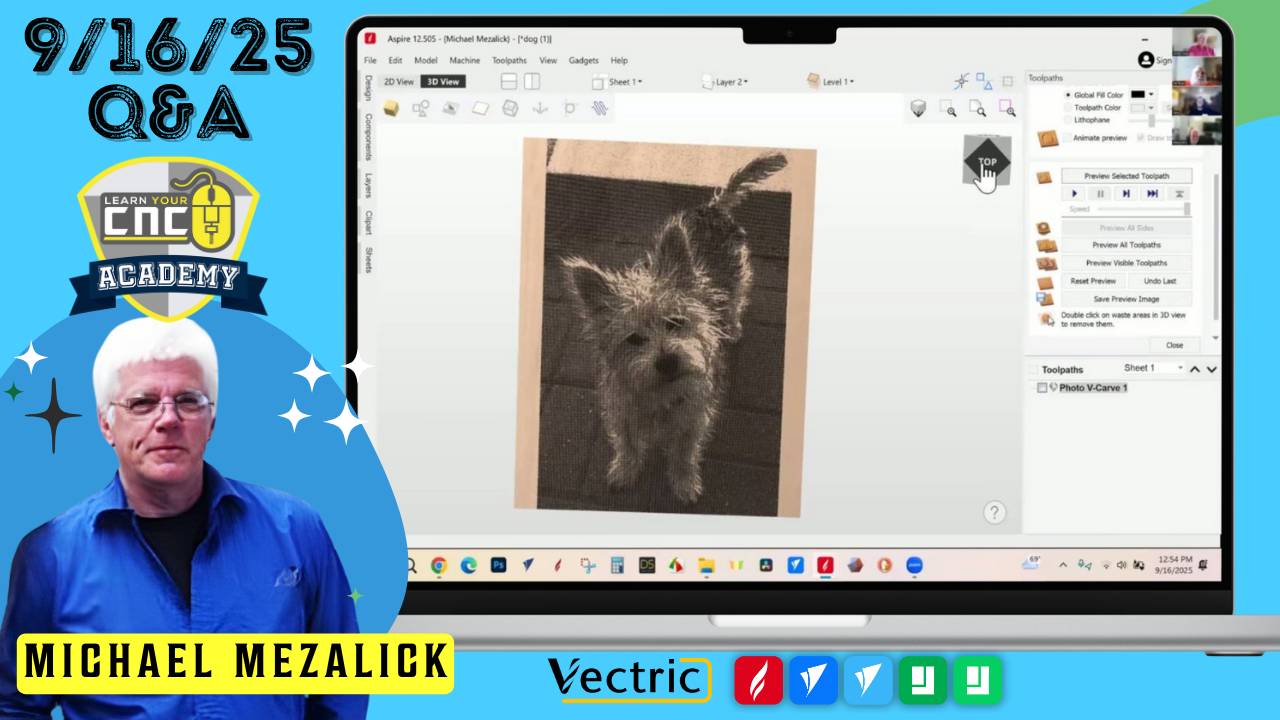

Photo VCarve Quality: Use sharper-angle bits (e.g., 30° or 15° V-bit) and tighter line spacing for cleaner photo carvings.

Questions Answered in this Q&A:

-

00:00:52 – How to get more detail carving a photo of wife & granddaughters in Aspire (bit choice, shape height, ball nose vs end mill).

-

00:10:55 – When to use a tapered ball nose instead of a standard ball nose.

-

00:13:13 – Clarification on base height vs shape height differences.

-

00:17:58 – How to carve only selected areas (like a face) with higher detail.

-

00:20:00 – How to adjust base/shape height interactively without entering numbers.

-

00:21:53 – How to taper or fade edges without losing detail.

-

00:23:56 – Why roughing toolpath estimated 89 hours, how to reduce carve time.

-

00:32:34 – Proper spindle speeds and chip load balance; dangers of always running at max RPM.=

-

00:38:41 – What’s the purpose of a zero plane, and when to use it?

-

00:44:30 – Can you align an object to guidelines in Aspire/VCarve?

-

00:49:29 – How to move toolpaths into new toolpath groups.

-

00:51:10 – Improving photo VCarve of his dog (bit angle changes).

-

00:53:36 – Using multiple tools for roughing vs finishing.

-

00:56:29 – Best way to create guitar body vectors (trace, node editing, outsourcing).

-

01:01:03 – How to create hand-carved edge effects using Aspire’s sculpting brushes.

-

01:05:15 – Quick ways to round rectangle corners (fillet, node handles, radius tool).

Keywords:

3d carving, aspire, vcarve, tapered ball nose, zero plane, limit plane, shape height, base height, toolpath efficiency, feed rates, rapid rate, photo vcarve, toolpath grouping, snapping guidelines, sculpting brush, guitar vectors, fillet tool

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!