06-03-2025 Q&A: Inlay Fit Issues, Mortise Pocket Inconsistencies, and Post Processor Fixes

Jun 03, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

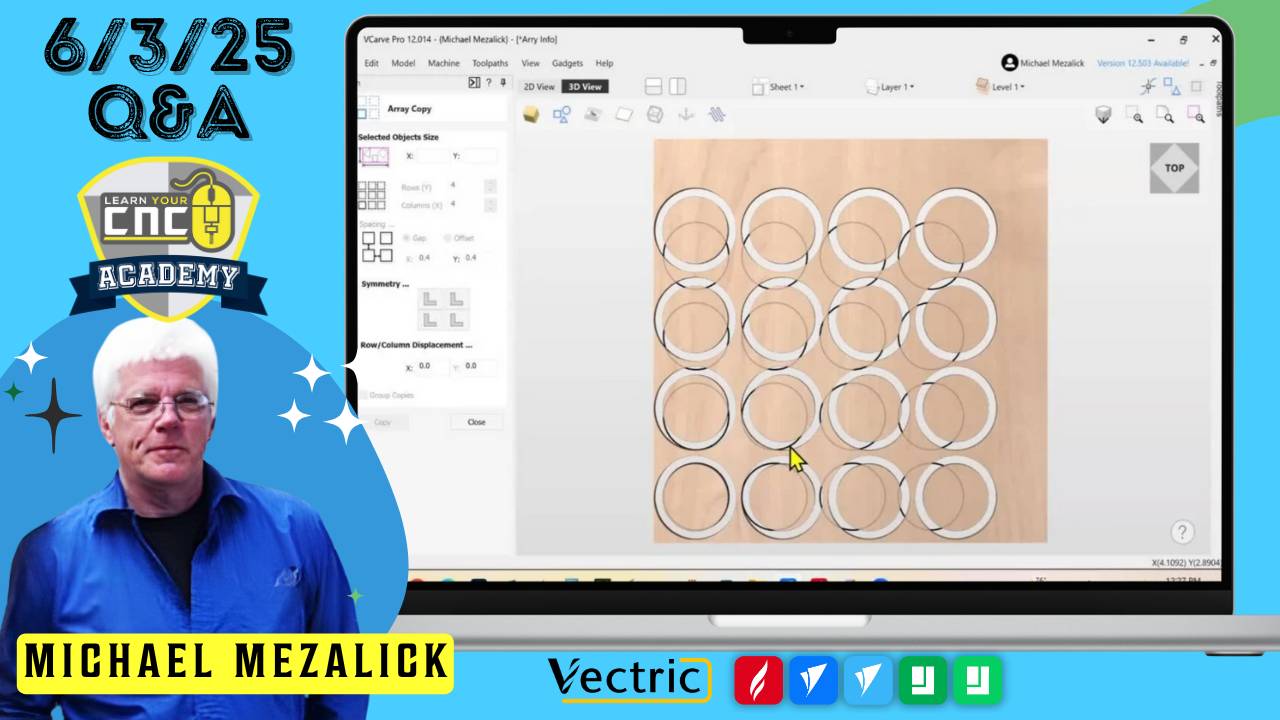

In this Q&A Meetup, we tackled several detailed troubleshooting questions related to Vectric software, toolpaths, and CNC hardware setups. We explored why inlays may not fit properly, how bit deflection and machine rigidity can affect pocket accuracy, and the best practices for managing post processors after software updates. Additional topics included spoil board prep, array toolpath alignment, and safe toolpath generation from third-party files like those from Etsy.

Key Tips Learned in this Q&A:

-

Inlay Depth and Fit: Double-check glue gap settings and make sure values match between design and toolpaths. A common mistake is mis-entering glue gap dimensions (e.g., entering 0.18 instead of 0.018).

-

Mortise Pocket Accuracy: A wider top cut may be caused by machine deflection or a worn-out collet. Replace collets every 500 hours of use or annually for hobbyists.

-

Collet Maintenance: A worn collet can result in inconsistent cuts. Visually inspect and replace them regularly to ensure proper bit grip.

-

Post Processor Transfers: After a Vectric update, you may need to manually copy your custom post processor into the new version’s "My_PostP" folder.

-

Toolpath vs. Vector Arrays: The toolpath array function includes tool diameter, while vector arrays do not, leading to visual misalignment.

Questions Answered in this Q&A:

-

00:01:28 – Why is my inlay not fitting? (Glue gap discrepancy and bit angle considerations)

-

00:09:18 – Why is my mortise pocket cut wider at the top than the bottom?

-

00:19:30 – Dado cuts not aligning – how can I fix alignment issues for a paper punch game

-

00:20:44 – Why are my double-sided vectors aligned in 2D but misaligned in 3D toolpath preview

-

00:29:01 – Why does my carve get deeper as the cut progresses? (Spoil board and collet checks)

-

00:34:02 – Post processor not triggering vacuum after Vectric update – how can I fix it?

-

00:44:37 – Should I seal my spoil board with shellac before surfacing it?

-

00:53:58 – Is it normal for Etsy files to not come with toolpaths?

-

00:57:57 – How do I get back to the main Zoom screen after clicking on someone’s image?

Keywords:

inlay troubleshooting, glue gap, mortise pocket, collet maintenance, post processor fix, vectric update, spoil board sealing, etsy cnc files, array toolpath, double-sided alignment, zoom view fix, cnc carving tips, vcarve toolpaths, cnc beginner advice, machine deflectioninlay troubleshooting, glue gap, mortise pocket, collet maintenance, post processor fix, vectric update, spoil board sealing, etsy cnc files, array toolpath, double-sided alignment, zoom view fix, cnc carving tips, vcarve toolpaths, cnc beginner advice, machine deflection

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!