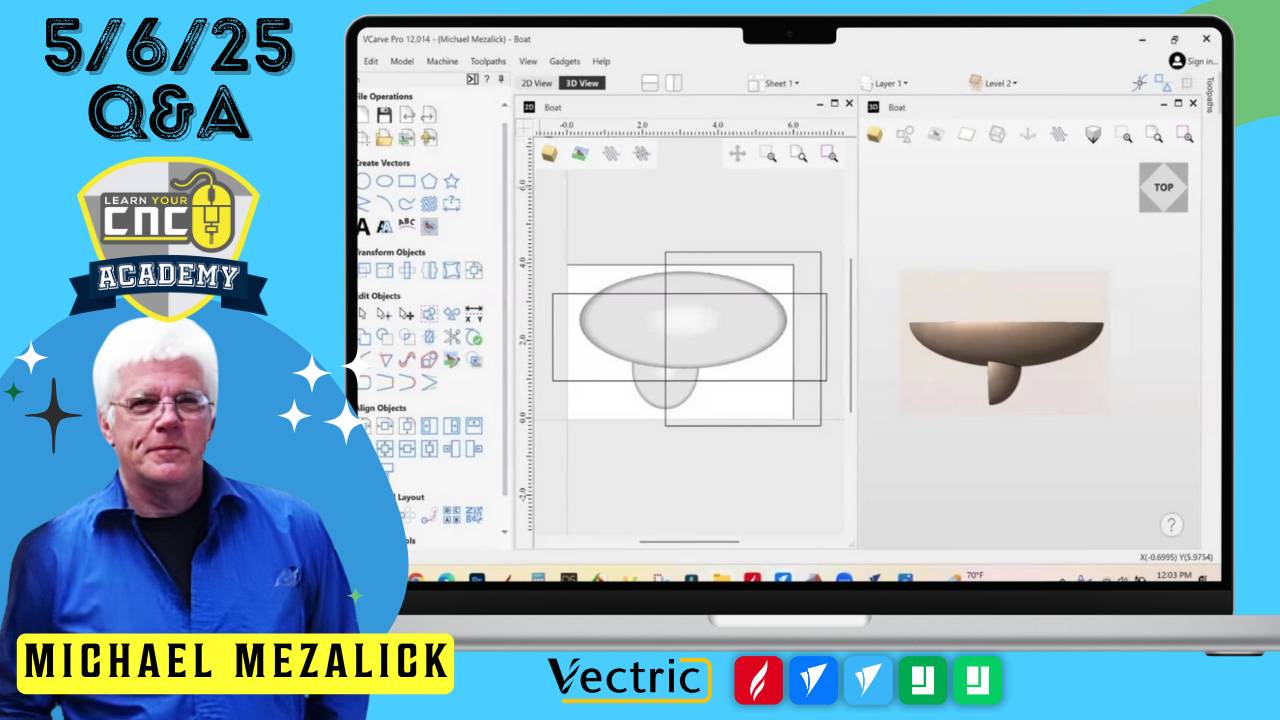

05-06-2025 Q&A: Boat Hulls, Honeycomb Designs, Braille Signage & Long Toolpaths

May 06, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

In this week’s Q&A session, we tackled complex design issues including modeling a boat hull in VCarve vs. Aspire, multiple methods for creating honeycomb patterns, and how to build Braille-compliant signage. We also explored techniques to break up long toolpaths for easier CNC operation and answered detailed design questions about circular pockets, drag knives, and interlocking segmented rings.

Key Tips Learned in this Q&A:

-

VCarve Limitations for Complex 3D Shapes: VCarve Pro’s molding toolpath can’t generate full 3D boat hull shapes—Aspire is needed for more detailed 3D modeling.

-

Honeycomb Pattern Strategies: You can create honeycomb designs using three primary methods—array copy with displacement, grouped offset polygons, and vector-guided copy—each with pros depending on complexity.

-

Braille Signage Compliance: For ADA-compliant Braille signage, you must follow strict guidelines for dot size, spacing, and layout. Use official resources and tooling techniques for consistent results.

-

Breaking Long Toolpaths: For large jobs, use GSender's "Start from Line" feature to safely resume cuts or consider post-processor “tape splitting” to break G-code into manageable chunks.

-

Designing Interlocking Rings: Custom-fit interlocking parts (like segmented rings or tracks) can be made with offset vectors and mirroring. Precision offsets help ensure proper fit.

Questions Answered in this Q&A:

-

00:02:59 – Can you model a boat hull in VCarve Pro using molding toolpath?

-

00:06:17 – How can I design a honeycomb pattern in VCarve?

-

00:16:12 – Any way to speed up carving of dense honeycomb patterns?

-

00:19:51 – Can glass be cut on a CNC using a drag knife or drag bit?

-

00:25:53 – How do I change a toolpath’s bit to a 60-degree v-bit if 90° is locked?

-

00:29:36 – How do I make Braille signs for ADA compliance?

-

00:34:21 – How can I break a long 147-hour toolpath into parts I can resume?

-

00:51:03 – What’s the best way to design interlocking ring segments or puzzle-style tracks?

Keywords:

boat hull, vcarve, aspire, 3d modeling, honeycomb pattern, cnc design, braille signage, ada compliance, toolpath splitting, gsender, cnc resume, drag knife, glass cutting, interlocking rings, vectric, post processor, cnc tips, learn your cnc

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!