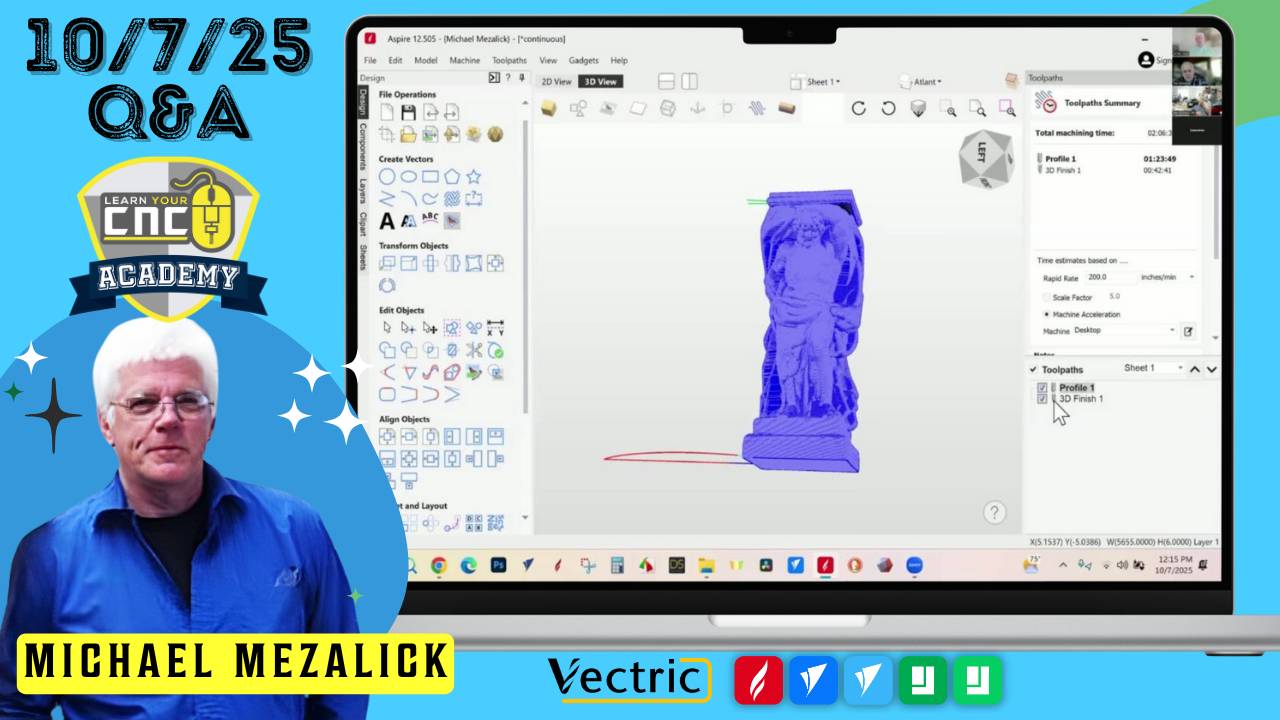

10-7-2025 Q&A: Continuous Cutting with Rotary, Finishing Tips, and Machine Acceleration Settings

Oct 07, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

In this Q&A session, Michael discussed advanced rotary toolpath strategies, including the origins and setup of continuous cutting using spiral wrap gadgets. The session also covered machine configuration and acceleration settings, finishing techniques for black walnut projects, creating connected cursive fonts for CNC cutting, using tabs for double-sided projects, and machining challenge coins in brass.

Key Tips Learned in this Q&A:

-

Continuous Cutting on Rotary Projects:

Use the spiral wrap gadget to create a continuous cut by projecting a shallow profile toolpath onto a 3D model. This minimizes acceleration/deceleration time and produces smoother rotary carvings. -

Safety Caution for Continuous Cutting: Be cautious with machine rewind after rotary jobs — some controllers may rapidly spin in reverse. Always be ready to hit stop if the model isn’t perfectly balanced.

-

Machine Acceleration Configuration: The “Angular Acceleration” value is used only for rotary toolpaths. If unavailable, test values manually (e.g., start with 1–1000) or check the stepper/servo motor specifications.

-

Finishing Black Walnut Projects: Tung or walnut oils yield a natural look but require multiple coats. For faster drying, use lacquer or shellac. Hardwax oils like Rubio Monocoat and Osmo offer a durable, natural finish.

-

Creating Cursive Letter Toolpaths: Weld overlapping vectors before toolpathing to prevent double cuts. Use Node Editing to connect disconnected letters cleanly.

-

Adding Tabs for Double-Sided Projects: Use the “Copy to Other Side” function to mirror vectors and tabs in Aspire’s double-sided setup for perfect alignment.

Questions Answered in this Q&A:

-

00:01:03 – Expanding on last week’s Rotary Spiral Wrap question and introduction to continuous cutting.

-

00:22:08 – How to find the angular acceleration value for Axiom AR16 machines using RichAuto controllers.

-

00:29:27 – Recommended finishes for a black walnut Last Supper carving.

-

00:35:24 – How to cut connected cursive letters properly in Vectric.

-

00:41:57 – Adding tabs on double-sided projects and adjusting round shapes in Aspire.

-

00:47:11 – Best practices for machining challenge coins from brass or aluminum.

-

00:50:42 – Suggestion for a community-driven Vectric improvement board.

-

00:52:39 – Clarification on accessing machine acceleration and toolpath timing settings in Aspire.

Keywords:

rotary, continuous cutting, spiral wrap, vectric aspire, machine acceleration, richauto controller, walnut finish, tung oil, hardwax oil, cursive fonts, welding vectors, node editing, double-sided project, 3d tabs, brass carving, challenge coin, cnc finishing, toolpath settings

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!