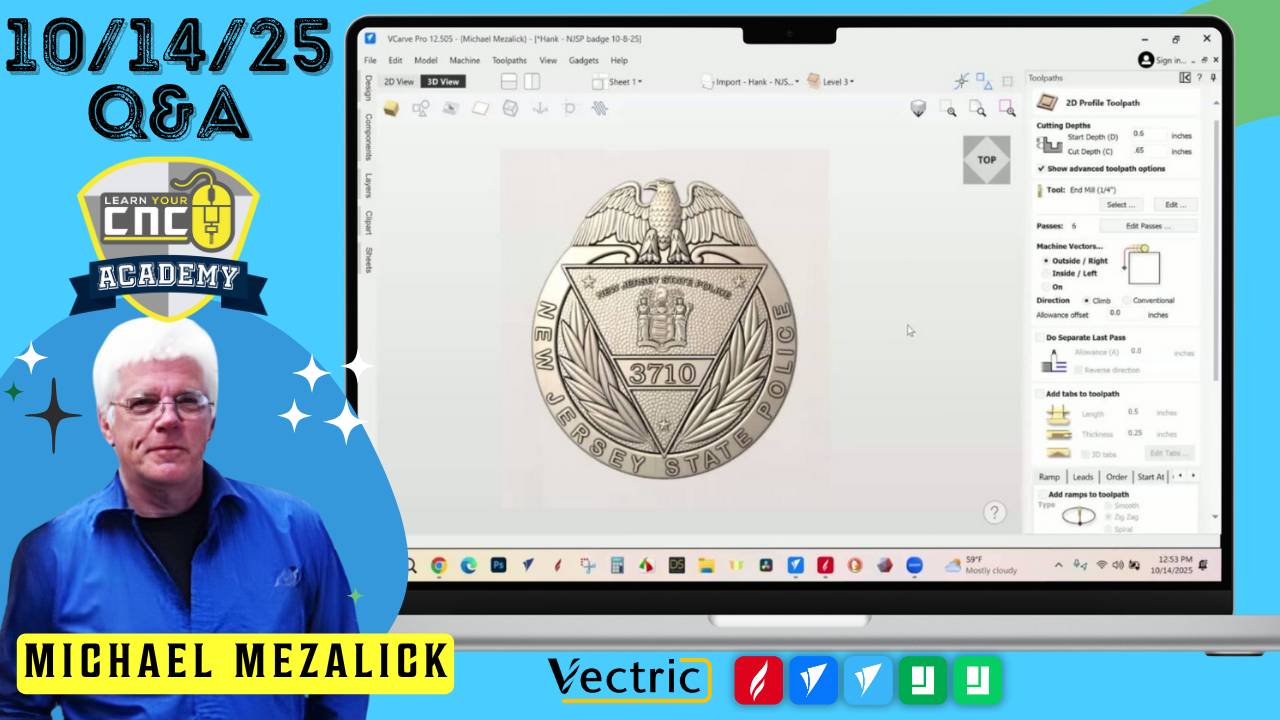

10-14-2025 Q&A: Two-Sided Tabs, Feed & Plunge Rates, and Time-Saving Strategies in 3D Carving

Oct 14, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

In this Q&A Meetup, Michael guided members through techniques for improving efficiency in both two-sided and 3D carving projects. The discussion included how to properly align tabs on double-sided carves, optimize toolpaths for reduced cutting time, troubleshoot post-processor and software update issues (particularly with Next Wave CNCs), and fine-tune feeds, speeds, and plunge rates for better machine performance. The group also covered advanced topics like start depth logic, raster vs. offset toolpaths, and when to use end mills vs. ball nose bits for roughing.

Key Tips Learned in this Q&A:

-

Adding Tabs in Two-Sided Projects:

Copy the vector and toolpath from one side to the other and recalculate to ensure tab alignment. For 3D models, use 3D tabs from the clipart library and mirror them to the opposite side. -

Feed & Plunge Rate Optimization:

In 3D carving, increase the plunge rate to about half of the feed rate (or more) since the machine rarely reaches full feed speed due to acceleration/deceleration limits. -

Reducing Cut Time:

Adjust safe Z heights, plunge rates, and feed speeds instead of changing the rapid rate or scale factor. A smaller safe Z (e.g., 0.2”) can significantly shorten machining time. -

Post-Processor Issues:

If “zigzag” toolpaths appear after updates (e.g., Next Wave’s Ready2Control), re-select or update the correct post processor, as firmware updates can reset them. -

Roughing Bit Selection:

Using a ball nose for roughing 3D models avoids gouging on curved surfaces compared to an end mill, especially when machining slopes or domes.

Questions Answered in this Q&A:

-

00:03:31 – How do I add tabs on a double-sided carve?

-

00:11:03 – How can I align vectors between multiple sheets in a two-sided project?

-

00:14:23 – Why do I get zigzag lines when running files on my Next Wave CNC after updating?

-

00:21:36 – How can I reduce carving time and handle narrow areas in my 3D Eagle badge project?

-

00:30:08 – What’s a safe way to adjust plunge rates without damaging the machine?

-

00:37:00 – How do Safe Z and Rapid Z settings affect machining time?

-

00:38:53 – Does using raster vs. offset finishing change carve time or surface quality?

-

00:41:18 – How to handle fine-profile areas like the eagle’s beak using multiple bits efficiently?

-

00:47:20 – How does start depth work and how to calculate proper Z-depth?

-

00:53:04 – Should roughing be done with end mills or ball nose bits? Why?

-

00:58:03 – What’s the difference between Z1 and Z2 rapid heights?

-

01:01:44 – Why can’t I merge a dish-shaped component with “merge” mode in Aspire?

Keywords:

two-sided tabs, vectric, aspire, vcarve, feed rate, plunge rate, next wave, ready2control, post processor, toolpath efficiency, safe z, rapid z, raster vs offset, stream deck, 3d carving, ball nose roughing, cnc efficiency, start depth, bake components

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!