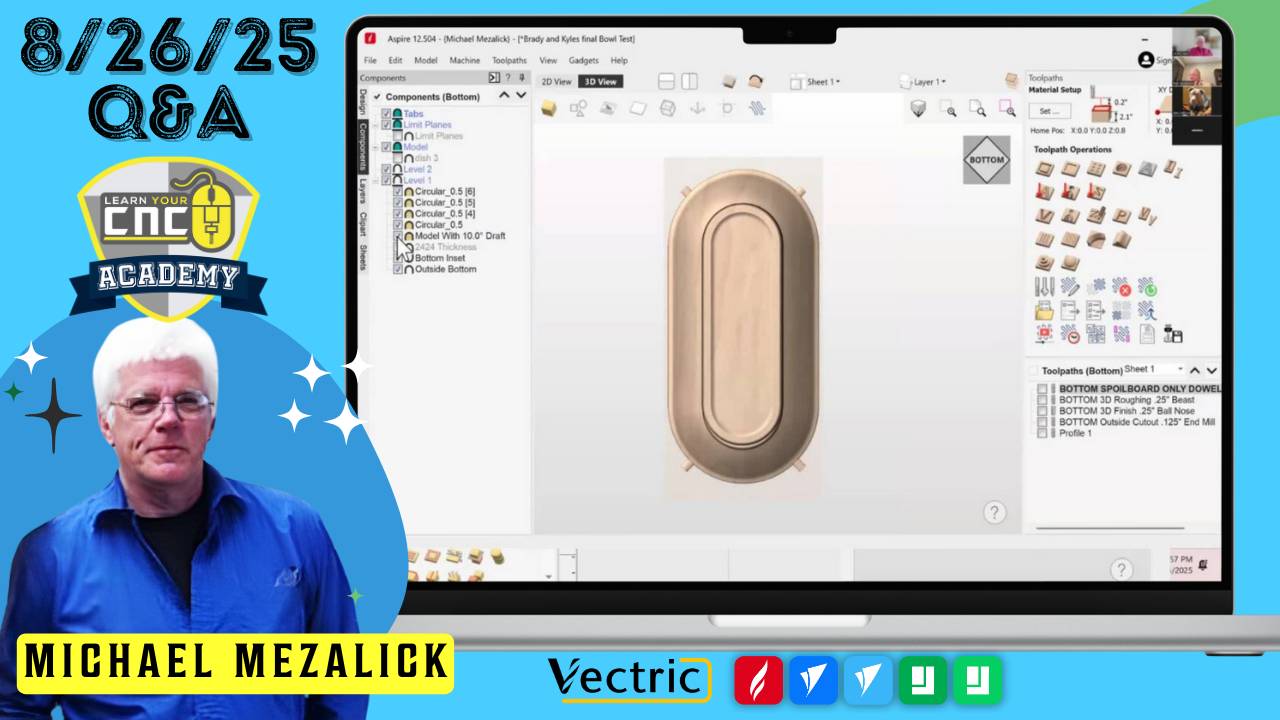

08-26-2025 Q&A: File Splitting, Tramming, Pocketing Issues, Multi-Species Inlays, Bowls, and Camshaft Design

Aug 26, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

In this Q&A session, we tackled a wide variety of CNC challenges including file cleanup and splitting, MDF toolpath lines and tramming, pocketing strategies when areas are missed, multi-wood inlays, handling raised ribbons and text, feeds and speeds for tapered ball nose bits, ensuring even thickness on two-sided bowls, and designing rotary camshafts. The discussion included practical troubleshooting steps, material recommendations, and workflow improvements.

Key Tips Learned in this Q&A:

-

File Splitting & Cleanup: Use a zero plane to clean up spikes in 3D models and split components into separate files by grouping vectors and creating components from the visible model.

-

Tramming for Cleaner Surfaces: Toolpath lines in MDF are often due to a spindle/router being out of tram. Check alignment in both X and Y axes for perpendicularity. Using moisture-resistant MDF options like Medex or Plum Creek can reduce warping.

-

Pocketing Strategies: When using pocket toolpaths, raster strategies reduce sanding by avoiding diagonal corner lines that result from offsets. Vectric now handles multi-tool pockets efficiently, automatically ordering from largest to smallest tool.

-

Inlays with Multiple Woods: Approach each color/species separately and allow glue to cure between steps. Refer to Kyle’s lessons 153 & 154 on inlays and the Vectric vector inlay tutorial for step-by-step guidance.

-

Projecting Text onto Models: In VCarve Pro, check the “Project toolpath onto 3D model” option to ensure lettering conforms to ribbons or curved surfaces.

-

Two-Sided Bowl Modeling: Exporting a dish as a 3D model and re-importing it allows for thickness verification and scaling of both sides together. Asymmetrical dowel holes prevent flip alignment errors. Tabs should be mirrored for consistent holding.

-

Feeds & Speeds: With small tapered ball nose bits, start very conservatively (e.g., 10 in/min feed) and gradually increase until reaching limits. Keep notes on results to build reliable reference data.

-

Camshaft Modeling in Rotary: Use two-rail sweeps and rotated vectors to create cam lobes at different orientations. Lobes are typically separated by about 100° between intake and exhaust centerlines.

Questions Answered in this Q&A:

-

00:00:54 – Cleaning up whiskey taster edges, splitting files, and difference between .tap and .nc files

-

00:04:42 – MDF toolpath lines, sanding, warping, and tramming issues

-

00:11:04 – Surfacing bit leaving lines on photo carvings

-

00:14:23 – Pocket toolpaths missing areas when using multiple bits

-

00:20:14 – Multi-species wood inlay project (tiger design)

-

00:23:28 – Ribbon/banner with text not sitting properly on top of design

-

00:33:07 – Feeds and speeds for a 0.015 radius tapered ball nose bit

-

00:36:40 – Two-sided bowl project: ensuring thickness consistency and dowel alignment

-

01:00:54 – Camshaft lobe design in rotary axis

Keywords:

cnc, vectric, vcarve, aspire, file splitting, zero plane, mdf toolpath lines, tramming, pocket toolpaths, raster vs offset, inlays, multi wood inlays, projecting text, ribbons, tapered ball nose feeds and speeds, bowl modeling, two sided projects, dowel alignment, camshaft rotary

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!