#95: Chamfer Toolpath Projects

Jun 09, 2022Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

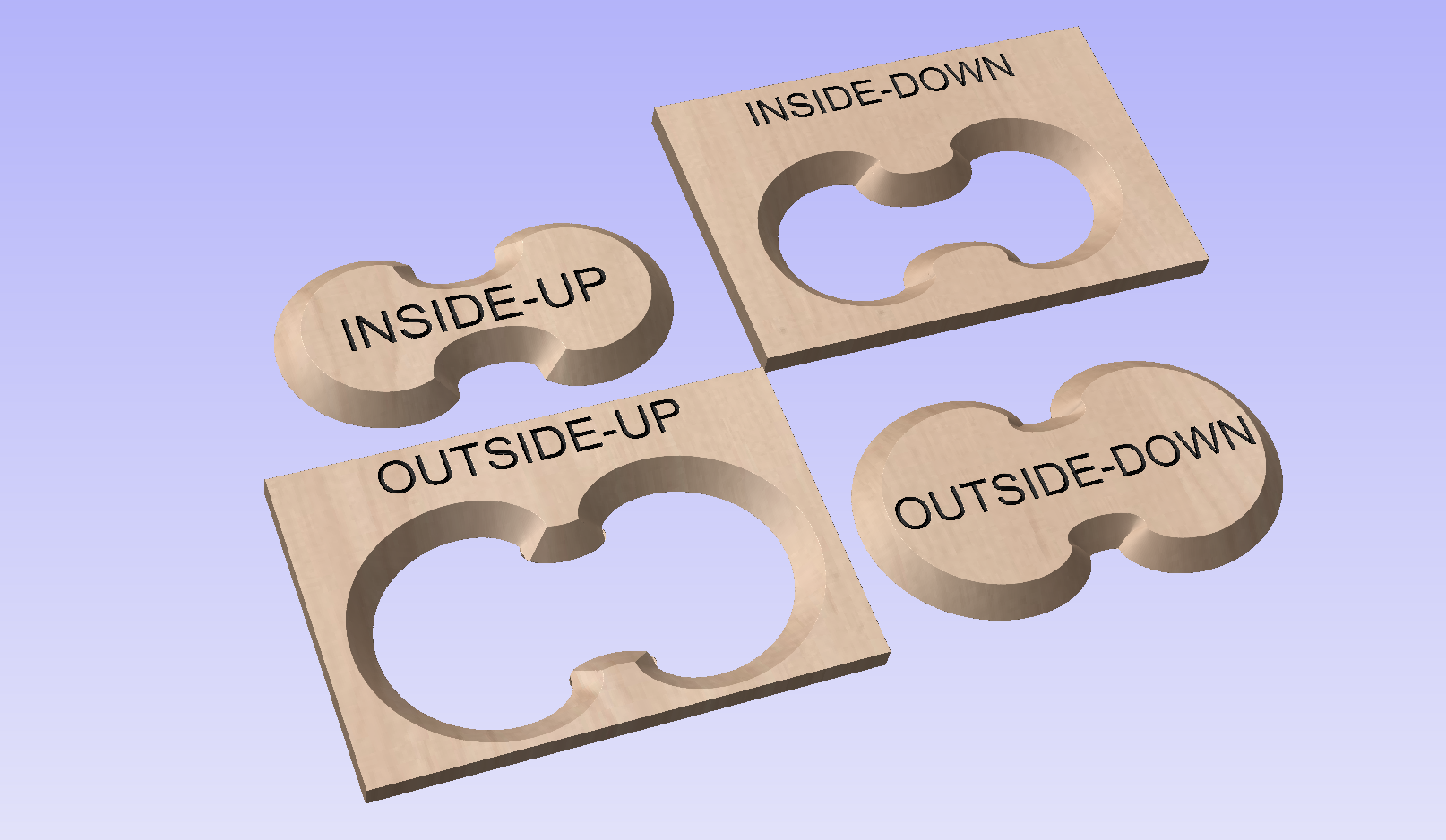

🔪 Sharpen your CNC skills with this in-depth exploration of the Chamfer Toolpath! Kyle breaks down its four core options: inside upwards , inside downwards , outside upwards , and outside downwards, demonstrating how each affects your cut. Learn about choosing the right tool—whether a V-bit for quick angled cuts or a ball nose for custom angles —and understand critical settings like start depth , cut depth , and overcut distance. Kyle highlights the pros and cons of using the Chamfer Toolpath versus the Molding Toolpath, especially concerning finish quality and machining time , and offers practical tips for avoiding common issues like visible steps in your chamfers. This lesson provides clear examples of applying chamfers to various projects , from decorative edges on signs and box tops to specialized inlays, giving you the knowledge to create precise and professional-looking angled edges.

Keywords for this lesson(helps with search):

chamfer toolpath, chamfering, angled cuts, v-bit, ball nose, engraving bit, inside upwards, inside downwards, outside upwards, outside downwards, start depth, cut depth, overcut distance, pass depth, molding toolpath, tool comparison, inlay, box top, sharp corners, rounded edges, tool selection, machining time, finish quality, vector properties, clipart, 2.5d carving

#toolpaths #vectricfeatures #intermediate #advanced #productivity #vcarve #aspire

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!