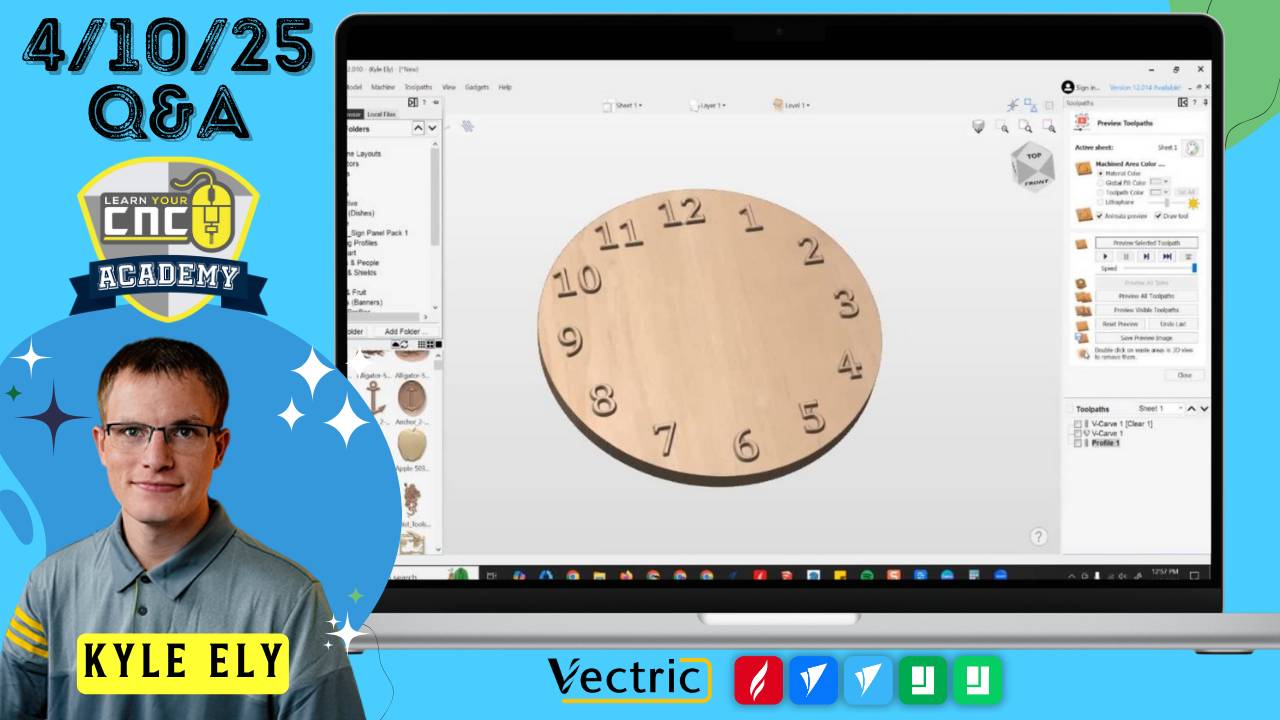

04-10-2025 Q&A: Raised Clock Numbers, Wavy Shelf Design, and Vectric 3D Precision Tips

Apr 10, 2025Note: You must be a member of the Learn Your CNC Academy Community to watch this replay. Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!

This session focused on advanced toolpath strategies including raised lettering in clock projects, working around Vectric’s pixel-based modeling for better 3D accuracy, and a full walkthrough for designing wavy shelf frames. We also discussed converting arcs, handling STL imports, laser picture toolpath compatibility, and managing custom inlays.

Key Tips Learned in this Q&A:

-

Raised Numbers with V-Carve: To make letters stand proud in VCarve, use a VCarve toolpath with a boundary and a clearance tool, then offset the boundary to avoid tool marks from the V-bit.

-

Improving 3D Accuracy in Aspire: Aspire models are pixel-based, so set modeling resolution to “Very High” or “Maximum” before creating 3D components for better dimensional accuracy.

-

Arc and Node Editing: Use Node Edit Mode (N) and shortcut keys (A for arc, D to delete spans) to convert or reshape lines and arcs easily.

-

Wave Frame Design Tip: Combine circle segments and copy them along a line or use simple node editing techniques to create evenly spaced wave forms.

-

Clock Inlay Advice: For clock inlays, individual number plugs are more efficient and precise than cutting one large round male inlay plug.

Questions Answered in this Q&A:

-

00:06:43 – How do I make raised letters on a clock using toolpaths instead of 3D modeling?

-

00:12:32 – Is there an online calculator for the VCarve/Aspire Toolpath Summary's Scale Factor?

-

00:15:47 – Why does Aspire add a buffer/padding around 3D models and how do I minimize it?

-

00:21:51 – Can I use STL models for parts that require a precise fit like lids and boxes?

-

00:30:01 – Is there a simple way to convert a line segment to an arc?

-

00:33:25 – How can I design the wavy frame for a flat-pack shelf like in lesson 137?

-

00:43:56 – Where can I find the Q&A lesson on distorted children's blocks?

-

00:46:02 – Can I load textures into VCarve and what file types work?

-

00:49:49 – For a number inlay on a clock, should I cut individual plugs or one large plug?

-

00:53:23 – Why doesn’t the Vectric laser picture toolpath work with NextWave CNC?

-

00:56:01 – Can I create a small box with a lid in SketchUp and export it for 3D printing?

Keywords:

vectric, aspire, vcarve, raised letters, clock toolpath, modeling resolution, 3d pixel issue, node edit, arc to line, flat-pack shelf, wave design, inlay tips, laser toolpath, v3m file, design and make, scale factor, toolpath calculator, sketchup, stl export, 3d box, nextwave cnc

Not a member of our Learn Your CNC Academy Community? Join over 1,500+ students today! Benefits include weekly Q&A Meetups, weekly project lessons, monthly CNC challenges, an active community of Vectric users, past replay lessons & project files, and so much more!